- About US

- Programs

- Research

- Life@NITTE

- Discover NITTE

- Alumni Website

- MANDATORY DISCLOSURE

- About US

- Governance

- Recognitions & Accreditations

- Undergraduate (B.Tech)

- Postgraduate

- Doctoral Programs

- Department of Basic Science & Humanities

- Artificial Intelligence & Data Science

- Artificial Intelligence & Machine Learning

- Biotechnology

- Civil Engineering

- Computer & Communication Engineering

- Computer Science & Engineering

- Computer Science (Full Stack Development)

- Computer Science & Engineering(Cyber Security)

- Electrical & Electronics Engineering

- Electronics & Communication Engineering

- Electronics Engineering (VLSI Design & Technology)

- Electronics & Communication (ACT)

- Information Science & Engineering

- Mechanical Engineering

- Robotics & Artificial Intelligence

- About

- Research Output

- Research Activities

- Photo Gallery

- JRF Notification

- Facilities

- Student Support

- Student Info

- Associations

- Entrepreneurship

- Other

Search Now

Physics Department

Physics Department

The Department of Physics, established along with the Institute in the year 1986 offers Engineering Physics Theory and Laboratory courses to first-year Engineering students and open elective papers in the eighth semester. It has well-equipped laboratories to facilitate the academic requirements of the students.The department has well qualified, experienced, and dedicated faculty, and the support staff. From the year 2022-23 Ph.D degree is awarded by Nitte Deemed to be University. The Department has received research funds from VTU & VGST and has published more than 70 research papers in journals of national and international repute.

Vision

To facilitate the students understand and apply basic knowledge in Physics to solve common problems through practical solutions, thus improving the quality of life.

Mission

- Providing quality education in the area of Physics to assist Engineering students to understand basic technology and apply them effectively

- To interact with faculty and students of all disciplines of Engineering stream to promote innovation, creativity, and professionalism with the larger ambition of taking the Institution to greater heights.

Facilities

Engineering Physics Lab

Engineering Physics Lab provides the first laboratory experience for engineering students

Read MoreEngineering Physics Lab

Engineering Physics Lab provides the first laboratory experience for engineering students. The Engineering Physics Laboratory is a core course and is offered to all students of Engineering at the first year level. The course consists of carrying out ten basic experiments based on various topics of Physics.

Research Facility

The department has research facilities in crystal growth, thin film deposition and z-scan technique

For any information regarding the admissions,mail us at: info@nitte.edu.in

Faculty

Research Centre

The department offers Ph.D. program under Nitte Deemed to be University. The department has received research funds from VTU & VGST and has published more than 75 research papers in journals of national and international repute.

Research Areas

- Thin film deposition and characterization

- Nonlinear optical studies

- Crystal growth and characterization

- Synthesis and characterization of magnetic and thermoelectric materials

Research Supervisors

| Sl.No. | Research Supervisors | Research Areas |

|---|---|---|

| 1. | Dr. Manjunatha K.B. | Third-order nonlinear optics |

| 2. | Dr. Raghavendra Bairy | Thin film deposition and characterization |

| 3. | Dr.Nagaraja B. S. | Magnetic materials and thin films |

| 4. | Dr. Shyam Prasad | Thermoelectric materials |

Research Grants

| Sl.No. | Title of the Project | Funding Agency | Amount (Lakhs) | Principal Investigator | Status |

|---|---|---|---|---|---|

| 1. | Tunable Nonlinear Optical Behavior of ITO-M (M=Zn,Ni,Co) Alloy Nanostructures for High Performance Laser Power Limiters |

Vision Group on Science and Technology, Govt. of Karnataka | 15.00 | Dr. Manjunatha K.B. | Received (Ongoing) |

| 2. | Development of Novel Metal Doped Semiconductor Thin Films with High Optical Nonlinearities to Protect Eye and Sensors | Vision Group on Science & Technology (VGST) Government of Karnataka | 5.00 | Dr. Manjunatha K.B. | Completed 2019 |

| 3. | All Optical Nonlinear Characteristics of Novel Materials For Optical Power Limiting Applications | NMAM Institute of Technology (Seed money) | 0.7 | Dr. Manjunatha K.B. | Completed 2017 |

| 4. | Development of Aluminum Doped Cadmium Sulfide Thin Film for Solar Cell Applications | NMAM Institute of Technology (Seed money) | 0.7 | Dr. Raghavendra Bairy | Completed 2017 |

| 5. | Growth Of Optical Crystal, Nano Crystals, Crystals On Polymer As Substrate For Various Optical Applications | Visvesvaraya Technological University(VTU), Belagavi | 3.75 | Dr. Sharada G. Prabhu | Completed 2012 |

RESEARCH FACILITIES

- Nano Science Research Laboratory

- Material Characterizations:

- Crystal growth apparatus with constant temperature bath:

- Centre for Thermoelectric and Magnetic Materials

Thin Film Laboratory:

The Thin Film Laboratory facilitates the preparation and study of thin films for device applications.

1. Spray Pyrolysis Equipment:

Holmarc’s Spray Pyrolysis system has been designed for research laboratories in thin films, especially for solar cell development. The system automates various fatigue and error creating processes involved in the technique when performed manually. Moreover, ergonomically designed chamber provides clean and healthy atmosphere suitable for modern lab conditions.

Parameters like dispensing rate of the solution and speed of spray head movement, which are difficult to control manually, are controlled precisely by PC based automation. A positive displacement pump controlled by stepper motor and microprocessor is used to dispense solution as per requirement. The spray head movement is also controlled by stepper motor driven linear stages in X and Y direction. The temperature of the substrate heater plate is controlled independently through a dedicated controller.

Model: HO-TH-04, Substrate temperature: 0 – 500 °C, Spray rate: 1 mL – 10 mL per minute.

2. Thermal Evaporation Unit (Vacuum deposition system):

The basic process of this method is sublimating source material(s) in powder form at high temperature, and a subsequent deposition of the vapor in a certain temperature region to form desired nanostructures.

This system uses resistive heating in which the material is heated until evaporation by means of an electrical current passing through a filament or metal plate where the material is deposited (Joule effect). The material vapor thus condenses in theform of thin film and deposits on the cold substrate surface placed in the chamber. This particular unit has a special arrangement of substrate heating up to 850°C in high vacuum.

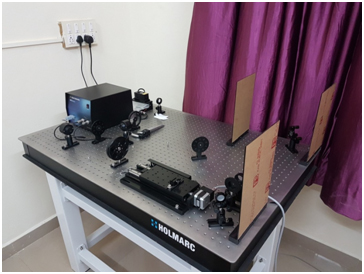

Z-Scan system

The Z-scan technique is a simple and popular experimental technique to measure nonlinear optical properties of materials. In this method, the sample is translated in the Z direction along the axis of a focused Gaussian beam and the far field intensity is measured as a function of sample position. Standard open aperture and closed aperture z-scan are covered with the kit. The two measurable quantities connected with the z-scan are nonlinear absorption and nonlinear refraction. These parameters are associated with the imaginary and real part of the third order nonlinear susceptibility, and provide important information about the properties of the material.Z-scan system has 532nm wavelength DPSS CW Laser with up to 100mW power and dual channel detector measurement unit with 2 Si Photodiode detectors and software.

The crystal growth apparatus (Rotek) is used for growing single crystals of organic and inorganic compounds at different temperature conditions (-20 °C to 50 °C) using slow solvent evaporation technique. The grown crystals can be characterized for structural, thermal and for nonlinear optical (NLO) applications.

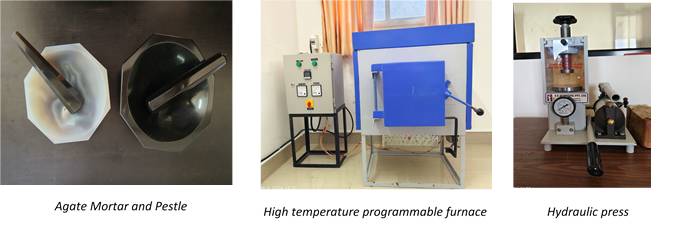

This lab facilitates to synthesize the thermoelectric and magnetic materials for clean energy power generation and sensor applications. The samples will be prepared using solid-state reaction technique which is a standard method to obtain polycrystalline materials from the solid reagents. The samples are ground using agate mortar and pestle to get homogeneous mixture. The high temperature programmable furnace which can reach up to 1300°C, is used for sintering the prepared samples which aids the interdiffusion of ions resulting in the formation of desired alloy. The lab also has a hydraulic press where powder samples are converted into pellet

Alumni Testimonials

Ms. Rhea Rodrigues

- DepartmentComputer Science & Engineering

- Designation Pursuing Ph.D in Oncology and Cancer Biology

- Organization University at Buffalo, New York

"NMAMIT allowed me the opportunity to take on new ventures. It could be pitching ideas for workshops or participating in projects that benefit society. Through these opportunities, I gained the confidence to make career-enhancing decisions. In addition, I would like to thank my professors for supporting me throughout my academic career."

Mr. Amol Revankar

- DepartmentComputer Science & Engineering

- Year of Passing 2019

- Designation Software Engineer

- Organization Accenture

"NMAMIT is an amazing place for students to build their skills and aptitude. The teaching staff are excellent in their fields. Students are great learners. The college not only focuses on academics but also on extra curricular activities promoting students' growth. Summing it up, I say, 'It was an honor for me to be a part of NMAMIT".

Ms. Deeksha Bangera

- Department Computer Science & Engineering

- Year of Passing 2019

- DesignationGraduate Engineer Trainee

- Campus RcruitedMercedes Benz

It was a wonderful experience at NMAMIT, Nitte. The faculty members were always encouraging and supportive. The pre-placement activities were very helpful with all the mock tests and training sessions.

Ms. Deeksha S N

- Department Computer Science & Engineering

- Year of Passing 2019

- DesignationSoftware Development Engineer

- Organization Oracle India Private Limited

I am indebted to NMAMIT for providing me excellent lecturers in my M.Tech programme and opportunities to develop my professional personality. NMAMIT has an amazing Placement cell that invites the best of companies to get their students hired for good positions. I express my deep gratitude to all my teachers of NMAMIT. I had the best facilities -a good library, labs, canteen, hostel, indoor and outdoor sports. I shall always remain grateful to NMAMIT.

Mr. Manjunatha U

- Department Computer Science & Engineering

- Year of Passing 2019

- Designation Graduate Engineer Trainee

- Organization Mercedes-Benz Research and Development India

My 4 years in college has been absolutely wonderful at NMAMIT. I have been extremely lucky to have professors who made my academic life comfortable thereby providing me time to explore other interests, opportunities to test my skills in various arenas - from technical clubs to sports clubs, from student chapters to college fests.

NMAMIT continuosly supports students by mentoring and counselling from the time of their entry to exit. They also have strict policies against ragging and sexual harassment to provide a safe eco space for growth of all individuals.

I cannot thank the Placement Department enough for the platform they provided for my career. My experience of college life has turned me into a wholesome person, ready to face new challenges in life every day and I wholeheartedly thank each and every one at NMAMIT who have made my college life memorable.

Ms. Pallavi

- Department Computer Science & Engineering

- Year of Passing 2014

- DesignationSenior Software Engineer

- Organization Happiest Minds Technologies Ltd.

"At NMAMIT, I have received equal opportunities in curricular and extra curricular activities. The institute has an outstanding library with a plethora of books for all disciplines of engineering. The faculty are co-operative and provide vital course materials and throw light on open queries throughout the engineering journey. Various companies visit the campus for placements. The placement department simultaneously provides required training and study materials to prepare every individual for interviews and to pursue their future endeavours."

Ms. Preethika Anchan

- Department Computer Science & Engineering

- Year of Passing 2019

- DesignationSolutions Engineer

- Designation VMware

"My sincere appreciation and gratitude to all the staff of NMAMIT and Abhyuday, the Training & Placement Department for their efforts in imparting quality technical education and aptitude training. I am forever grateful to them for helping me to grab the amazing opportunity that came into my life of being a part of VMware".

Mr. Rameez Shuhaib

- Department Computer Science & Engineering

- Year of Passing 2018

- DesignationSoftware Engineer

- Organization Shuttl

"The NMAM institute of Technology has always provided me an opportunity to broaden my skills and to focus on my areas of specific interests in Academics. The friendly attitude of the professors and their willingness to readily offer a helping hand has helped me to improve technically as well as personally. I'm proud to be an NMAMITian".

Mr. Shashank S Shetty

- Department Computer Science & Engineering

- Year of Passing 2018

- DesignationSoftware Engineer

- Organization MakeMyTrip & Goibibo

"Education is the passport to the future, for tomorrow belongs to those who prepare for it today."- Malcolm X

I am grateful to NMAMIT, Nittefor providing me opportunities for growth. I had an amazing college journey. “To reach the top of the ladder, one should have a great foundation” they say. NMAMIT has given me just that to improve my professional and soft skills. Students in NMAMIT have the benefit of exposure to the challenges of modern technology. They have opportunities to upgrade their skills with a number of events & activities within the college and at inter collegiate levels. NMAMIT has an amazing bunch of experienced faculty. I have benefited greatly from the friendly, supportive student-teacher interactions. Students and teachers strive to reach higher by stretching their limits.

The college has a very approachable Placement department, where anyone can seek help, be it academic, personal or career related. I have benefited a lot from this. The campus placements are growing constantly with top firms visiting NMAMIT and the placement numbers steadily rising. I would strongly recommend my friends and family to consider NMAMIT as their college of preference.

Ms. Siri Vikyath

- Departmentcomputer Science & Engineering

- Year of Passing 2018

- DesignationSenior Quality Assurance Engineer

- Organization Informatica

"My college has played a very important role in the larger journey of my life. It has helped me get where I am today. I will always be grateful to NMAMIT for helping me grow. I am a proud NMAMITIAN. "

Ms. Vandana Nayak

- DepartmentComputer Science Engineering

- Year of Passing 2018

- DesignationSoftware Development Engineer

- Organization IBM India Software Labs

NMAMIT, Nitte has gained immense popularity for the quality of education, faculty and the amazing placement opportunities it offers. The college management is really good and the environment very pleasant and green. Placement department works extra hard to get most of the students placed in reputed companies. Four years of my journey in this college was incredible and lively. Cheers!!

Ms. Varsha P

- DepartmentComputer Science Engineering

- Year of Passing 2018

- Designation Software Engineer

- Organization Informatica

"I joined NMAMIT with hopes of graduating with a job in hand. (I had been allocated a seat in a college in Bangalore but desired to study in my native place and the best choice was NMAMIT.) The advantage of NMAMIT over other colleges in the city is the beauty of nature we get to witness, the humane nature of the people, and the encouraging teachers. They are supportive inside and outside the classroom with academic and extra curricular activities- cultural or sports or just about anything. NMAMIT faculty are like family . They live and teach by example. My journey of 4 years in NMAMIT was joyful and memorable. I have learnt valuable life' lessons along with the curriculum. The brilliant minds at Abhyuday, Placement, make my college truly the best experience one could ever have.

Mr. Vineeth Bangera

- DepartmentComputer Science Engineering

- Year of Passing 2014

- DesignationUX Designer

- Organization NetApp

"I'm fortunate to have found great mentors at NMAMIT who have molded me to explore beyond my horizon by encouraging me to conduct activities that were not limited to a single domain. This ability to think creatively and laterally has definitely helped me find answers during challenging situations. Furthermore, I strongly believe the NMAMIT community including the staff, alumni, and my peers have played a crucial role in my professional career."

Mr. Akshay Kumar

- Department Computer Science

- Year of Passing 2016

- Designation Lead Software Developer

- Organization Collins Aerospace

Well, it is often said “Your attitude, not your aptitude, will determine your altitude”. NMAMIT has been that source which has fine tuned my attitude to help me reach the altitude where I stand today. From enhancing one's self confidence to exploring the credibility, to dream bigger and proceed towards achieving the goals our educational institutions and the faculty, play a major role. I am extremely happy that I got an opportunity to be a student of this wonderful institution which has shaped every individual to come out with flying colors in their life.

The confidence imbibed in each and every student and the support rendered by all the faculty members in NMAMIT is immense and this leads to self development of an individual. Ample opportunities have been provided by the institution to improve oneself in academics as well as extra - curricular activities which definitely enhances the leadership skills in an individual. I am thankful to each and every teacher who has helped me to be a better person in all four years of Engineering. Finally, it is believed that "Education is the passport to the future, for, tomorrow belongs to those who prepare for it today", so keep preparing, keep improving, keep exploring and never give up on your dreams.

Mr Glenn Thomas Alex

- Department Computer Science & Engineering

- Year of Passing 2019

- Designation Proactive Customer Success Engineer

NMAMIT has always been my second home. It's where I discovered a part of myself, and who I wanted to become. Hearing the word 'Nitte' makes me smile and that's the place I want to go back to, if given a chance.This is why I try my best to help the juniors in their academics, especially with regard to placements, because the outstanding feature of this college is the brilliant placements offered at the end of 4 years.

Mr Kartikay Dwivedi

- Department Computer Science

- Year of Passing 2016

- Designation Cloud Infrastructure Administrator

- Campus Recruited VMware

The three most important factors influencing success for an engineer are ' Learning Environment, Branch of interest and opportunity for Placements'. NMAMIT provides all three - the ideal atmosphere for learning, best faculty (as I had in CSE who are also friendly and helpful) and, good placements.

Abhyuday, the counselling, welfare, training & placement department works efficiently with concern, to groom all the students to prepare them for life and find placements in the best possible companies. (Placements begin on entering the final year), I even had the rich privilege and freedom of running a program to train the 3rd year students to prepare for placements along with a team of like minded campus recruited students, a process that trains us in compassionate leadership.

Dr. MANJUNATHA K B

- Designation Professor

- Email manjukb15@nitte.edu.in

- Contact No.

- Joining date 08-08-2012

- Ph.D. in Physics from National Institute of Technology Karnataka - 2014.

- M.Sc. in Physics from Mangalore University, Mnagalore-2005

- B.Sc. (Physics, Mathematics & Computer Sci.) from Mangalore University -2003

- Associate Professor in NMAM Institute of Technology from January, 2020

- Visiting Fellowship Programme in Jawaharlal Nehru Centre for Advanced Scientific Research (JNCASR), Bangalore from May, 2019 to June, 2019.

- Assistant Professor Gd-III in NMAM Institute of Technology from March, 2014 to December, 2019.

- HoD, Department of Physics in NMAM Institute of Technology from July, 2016 to June, 2019.

- Assistant Professor/Lecturer in NMAM Institute of Technology from August, 2012 to March, 2014.

- Senior Research Fellow in National Institute of Technology Karnataka from August, 2011 to July, 2012.

- Project Scientist in National Aerospace Laboratories (NAL), Bangalore from May, 2007 to July, 2007.

- Project Graduate Trainee in National Aerospace Laboratories (NAL), Bangalore from May, 2006 to April, 2007.

- Lasers and Nonlinear optics

- Nanostructured materials

- ISO Coordinator

- NAAC Coordinator

- Member, Photonics Society of India (PSI)

International Journals

- Manjunatha K.B., Dileep Ramakrishna, B.J. Rudresha, Albin Antony, P. Poornesh, "Design, synthesis and nonlinear optical characterization of novel mixed ligand ruthenium metal-organic complex" Optical Materials107, 110068 (2020).

- Ramesh S. Bhat, Manjunatha K.B., "Corrosion performance of Zinc Based Binary and Ternary Alloy Coatings" Chemical Data Collections 28, 100440 (2020).

- K.V. Basavarajappa, Y. Arthoba Nayaka, H.T. Purushothama, R.O. Yathisha, M.M. Vinay, B.J. Rudresha, Manjunatha K.B., "Optical, electrochemical and current_voltage characteristics of novel coumarin based 2,4-dinitrophenylhydrazone derivatives" Journal of Molecular Structure 1199 (2020) 126946.

- Manjunatha K.B., Ravindra Rajarao, P. Poornesh, Rudresha B.J., G. Umesh, B. Ramachandra Bhat, "Enhanced photostability and optical nonlinearity of nickel and cobalt organometallic complexes" Optical Materials 89, 494-497 (2019).

- B. Sudarshan Acharya, Anusha, Albin Antony, Aninamol Ani, I.V. Kityk, K.Ozga, A. Slezak, J. Jedryka, P. Poornesh, K.B. Manjunatha, Shashidhara Acharya, "Strategic improvement of second and third harmonic generation in multifunctional Cu-Sn-S3 ternary semiconducting thin films" Optics and Laser Technology 120 (2019) 105748.

- U.G. Deekshitha, Krithika Upadhya, Albin Antony, Aninamol Ani, M. Nowak, I.V. Kityk,J. Jedryka, P. Poornesh, Manjunatha K.B., Suresh D. kulkarni, "Effect of Na doping on photoluminescence and laser stimulated nonlinear optical features of ZnO nanostructures", Materials Science in Semiconductor Processing 101 139-148 (2019).

- M.S. Bannur, Albin Antony, K.I. Maddani, P. Poornesh, Manjunatha K.B., Suresh D. Kulkarni, K.S. Choudhari, "Role of Ba in engineering band gap, photoluminescence and nonlinear optical properties of SnO2 nanostructures for photovoltaic and photocatalytic applications", Superlattices and Microstructures 122, 156-164 (2018).

- Manjunatha K.B., Ravindra Rajarao, G. Umesh, B. Ramachandra Bhat, P. Poornesh. Optical nonlinearity, limiting and switching characteristics of novel ruthenium metal-organic complex. Optical Materials 72, 513-517 (2017).

- Manjunatha K. B., Ravindra Rajarao, G. Umesh, B. Ramachandra Bhat, Poornesh P. All-optical switching and limiting properties of Ru (II) Schiff base complex for nonlinear optical applications. Laser Physics 27, 085401 - 085406 (2017).

- Albin Antony, S. Pramodini, I.V. Kityk, M. Abd-Lefdil, A. Douayar, F. Cherkaoui El Moursli, Ganesh Sanjeev, K.B. Manjunatha, P. Poornesh, "Effect of electron beam on structural, linear and nonlinear properties of nanostructured Fluorine doped ZnO thin films" Physica E, 94 190-195 (2017)

- Manjunatha K. B., Dileep R., G. Umesh, M. N. Satyanarayan and B. Ramachandra Bhat "All Optical Nonlinear and Switching Characteristics of a Novel Ruthenium Complex", Optical Materials 36, 1054-1059, 2014.

- Manjunatha K. B., Dileep R., Vikas M. Shelar, G. Umesh, M. N. Satyanarayan and B. Ramachandra Bhat, "Third-Order Nonlinear Optical, Optical Power Limiting and All-Optical Switching Studies on Palladium Complexes", Synth. React. Inorg. Met.-Org. Chem. 44(2), 282-290 (2014).

- Manjunatha K. B., Dileep R., G. Umesh and B. Ramachandra Bhat, "Nonlinear optical and all-optical switching studies of novel ruthenium complex", Optics & Laser Technology, 52, 103-108, (2013).

- Manjunatha K. B., R. Dileep, G. Umesh and B. Ramachandra Bhat (2013). "Nonlinear Optical and All-Optical Switching Studies of Palladium (II) Complex." Materials Letters, 105, 173-176, (2013).

- Manjunatha K. B., Dileep R., G. Umesh and B. Ramachandra Bhat, "Study of Third-Order Nonlinear Optical and All-Optical Switching Properties of Palladium Metal-Organic Complex", Optical Materials, 35(7),1366-1372 (2013).

- Laxminarayana Kamath, Manjunatha K. B., Seetharam Shettigar, B. Narayana, S.Samshuddin and B.K.Sarojini, "Investigation of Third-Order Nonlinear and Optical Power Limiting Properties of Terphenyl Derivatives" Optics & Laser Technology, 56, 425-429. (2014).

- Y.L.N. Murthy, K.P. Suhasini, V. Veeraiah, G. Umesh, Manjunatha K.B., V. Christopher, "Synthesis, characterization and evaluation of the photophysical and nonlinear optical behaviour of novel 4-substituted arylidene-2-[5-(2,6-dichlorophenyl)-3-methyl-1,2-oxazol-4-yl]-1,3-oxazol-5-ones", Dyes and Pigments, 99(3), 713-719 (2013).

- Rudresha B. J., Manjunatha K. B., G. Umesh, B. Ramachandra Bhat, "Octupolar metal complexes for third order nonlinear optical studies", Chemical Physics Letters, 542, 159-163 (2012).

- K. Naseema, Manjunatha K. B., K.V. Sujith, G. Umesh, Balakrishna Kalluraya, Vijayalakshmi Rao, "Third order optical nonlinearity and optical limiting studies of propane hydrazides", Optical Materials, 34, 1751-1757 (2012).

- Ananthi N., Balakrishnan U., Velmathi S., Manjunatha K. B., G. Umesh, "Synthesis, Characterization and Third Order Non Linear Optical Properties of Metallo Organic Chromophores", Optics and Photonics Journal, 2, 40-45 (2012).

- Y. Narayana, Navin N. Bappalige, G. Umesh and Manjunatha K. B.,"Second and Third harmonic conversion efficiency of two new organic crystals by Nd: YAG laser - A comparative Study" Inernational Journal of Science Research, 1(4), 298-300 (2013)

- J. Nagappaa J. Mahadeva, R. Somashekara, C. V. Yalemaggad, G. Umesh and Manjunatha K. B., "Non Linear Optical Properties of Banana Shaped Liquid Crystals", Molecular Crystals and Liquid Crystals, 540(1), 88-93, (2011).

- K. Naseema, M. Shyma, Manjunatha K. B., A. Muralidharan, G. Umesh, Vijayalakshmi Rao "χ(3) measurement and optical limiting studies of urea picrate", Optics & Laser Technology, 43, 286-1291, (2011).

- K. Naseema, Vijayalakshmi Rao, Manjunatha K. B., G. Umesh, Sujith K. V., and Kalluraya, Balakrishna, "Synthesis, characterization and studies on nonlinear optical parameters of 4-amino-5-(4-nitrophenyl)-1, 2, 4-triazole-3-thione", Journal of Optics, 39(3), 143-148 (2010).

- K. Naseema, K.V Sujith, Manjunatha K. B., Balakrishna Kalluraya, G. Umesh and Vijayalakshmi Rao, "Synthesis, characterization and studies on the nonlinear optical parameters of hydrazones", Optics & Laser Technology, 42 (5), 741-748 (2010).

- P. Poornesh, K. Ravi, G. Umesh, P.K. Hegde, M.G. Manjunatha, Manjunatha K. B., A.V. Adhikari, "3,3′- Benzene - 1 , 4 - diylbis [ 1 - (substituted) phenylprop-2-en-1-one] derivatives: A new class of materials for third-order nonlinear optical applications", Optics Communications, 283(7), 1519-1527 2010.

- P. Poornesh, P.K. Hegde, G. Umesh, M.G. Manjunatha, Manjunatha K. B., A.V.Adhikari., "Nonlinear optical and optical power limiting studies on a new thiophenebased conjugated polymer in solution and solid PMMA matrix", Optics and Laser Technology, 42(1), 230-236 (2010).

- S. Shettigar, G. Umesh, P. Poornesh, Manjunatha K. B., Abdullah Mohammed Asiri., "The third-order nonlinear optical properties of novel styryl dyes" Dyes and Pigments, 83(2), 207-210 (2009).

- P. Poornesh, G. Umesh, P. K. Hegde, M.G.Manjunatha, Manjunatha K.B., A.V.Adhikari. "Studies on third-order nonlinear optical properties and reverse saturable absorption in polythiophene/poly (methylmethacrylate) composites", Applied Physics B: Lasers and Optics, 97(1), 117-124 (2009).

- P. Poornesh, S. Shettigar, G. Umesh , Manjunatha K. B., K. Prakash Kamath, B.K. Sarojini, B. Narayana., "Nonlinear optical studies on 1,3-disubstituent chalcones doped polymer films", Optical materials, 31(6), 854-859 (2009).

National Journals

- N. Prabhu, A. Jayarama, K. Subrahmanya Bhat, Manjunatha K. B., G. Umesh and V. Upadhyaya, "Physicochemical Studies on Thienyl Chalcone Derivative for Nonlinear Optical Application", Indian Journal of Materials Science, 2013 (151230), (2013).

- K. Janardhana, V. Ravindrachary, P.C. Rajesh Kumar, G. Umesh, Manjunatha K. B. and Ismayil, Third order optical non-linearity of a novel chalcone derivative through Z-scan technique, Indian Journal of Pure & Applied Physics, 51, 844-850 (2013).

Papers Presented In International And National Conferences (Selected)

- Manjunatha K.B., Ravindra Rajarao, Poornesh P. "Third-Order Nonlinear Optical Studies of Novel Ruthenium Metal-Organic Complex" International Conference on Material Science for Societal Advancement (MSSA-2020), Osmania University, Hyderabad, January 20-22, 2020.

- Manjunatha K.B., Bannur M.S., Albin Antony, Maddani K.I., Poornesh P., Suresh D. Kulkarni, Choudhari K.S. "Effect of Ba in tuning energy band gap, photoluminescence and nonlinear optical properties of SnO2 thin films for optoelectronic device applications" 3rd International Conference on Optoelectronic and Nano Materials for Advanced Technology (ICONMAT 2019), Kochi, India, January 03-05, 2019.

- Manjunatha K.B., Albin Antony and Poornesh, "Nonlinear Optical Studies of Carboxylic Acid Functionalized Multiwall Carbon Nanotubes" National Conference on Condensed Matter Physics and Applications (CMPA-2017), Manipal Institute of Technology, Manipal, September 22-23, 2017.

- Manjunatha K.B., Ravindra R., G. Umesh and B. Ramachandra Bhat "Third-Order Nonlinear Optical and Optical Power Limiting Properties of Nickel Metal-Organic Complex" National Conference on Emerging Trends in Science and Engineering (NCETSE - 2017), SMVITM, Bantakal, 23 & 24 February 2017.

- Manjunatha K. B., S. Shettigar, Ravindra R., G. Umesh and B. Ramachandra Bhat, "Investigation of Nonlinear Optical and All-Optical Switching Properties of Novel Ruthenium Complex" Photonics - 2012, International Conference on Fiber Optics and Photonics, Indian Institute of Technology Madras, Chennai, India, December 09-12, 2012.

- Manjunatha K. B., Dileep R., Shelar Vikas M., G. Umesh, M. N. Satyanarayan and B. Ramachandra Bhat, "Third-Order nonlinear optical properties and optical switching of Palladium (I) Complex", International Conference on Light, National Institute of Technology Calicut, Kerala, India, 23 -25 May 2011.

- Manjunatha K. B., Dileep R., Shelar Vikas M., Hidayath Ulla, G. Umesh, M. N. Satyanarayan and B. Ramachandra Bhat, "Nonlinear refractive index and reverse saturable absorption of Thiolato complexes of Ruthenium" Photonics - 2010, International Conference on Fiber Optics and Photonics, Indian Institute of Technology Guwahati, Guwahati, India, December 11-15, 2010.

- Manjunatha K. B., Dileep R., Shelar Vikas M, G. Umesh, M. N. Satyanarayan and B. Ramachandra Bhat, "Third-Order nonlinear optical properties of Palladium (I) complex " Photonics - 2010 , International Conference on Fiber Optics and Photonics, Indian Institute of Technology Guwahati, Guwahati, India, December 11-15, 2010.

- Manjunatha K. B., Dileep R., Shelar Vikas M., G. Umesh, M. N. Satyanarayan and B. Ramachandra Bhat, "Nonlinear optical properties of Thiolato complex of Ruthenium in solution and PMMA matrix using single beam Z-scan technique" NLS-19, RRCAT, Indore, December 1-4, 2010.

- Manjunatha K. B., Shelar Vikas M, Shettigar S., G. Umesh and M. N. Satyanarayana, "Third-Order Nonlinear Optical and Optical Power Limiting Studies on Amino Substituted Chalcones", International Conference on Recent Trends in Materials and Characterization RETMAC 2010, NITK, Surathkal, India, February 14-15, 2010.

Workshops/seminars attended:

- Attended (online) One Week Faculty development programme on "NBA and NAAC Accreditation Process", 4 - 8 June, 2020, M.S. Ramaiah Institute of Technology, Bangalore.

- Attended (online) Faculty development programme on "Physics of Materials", 28 - 30 May, 2020, Jain (Deemed to be university), Bangalore.

- Attended (online) One Week Faculty development programme "ERUDITION 2020", 23 - 28 May, 2020, Payyanur College, Payyanur.

- Participated six day GIAN course on "Multifunctional Advanced Nanomaterials and their Application", 03-08, December 2018, Mangalore University, Mangalore.

- Attended one day' workshop on "Advanced Chemical Research for Engineering Applications", July 20, 2017. NMAM Institute of Technology, Nitte.

- Attended two day' workshop on "Virtual Laboratory", December 1 & 2, 2016, NMAM Institute of Technology, Nitte.

- Participated four day' workshop on "Therapeutic Counseling for Teachers in Higher Education", May 17-20, 2016. NMAM Institute of Technology, Nitte.

- Attended two day workshop on "Nano-Science and Nano-Technology", March 11-12, 2016. Alva's Institute of Engineering and Technology, Moodbidre.

- Attended two day' workshop on "Modern Trends in Chemical Research and Their Applications", July 10-11, 2014. NMAM Institute of Technology, Nitte.

- Participated the two day' workshop on "Advanced Materials Research for Device Applications", July 25-26, 2013. NMAM Institute of Technology, Nitte.

- Attended one day symposium on "Recent Advances in Photonics", March 29, 2011. CAMP, Manipal University, Manipal, INDIA.

- Participated the "Workshop on Experimental Techniques in Nonlinear Optics", January 19-20, 2011, Raman Research Institute, Bangalore, INDIA.

- Attended one day symposium on "Laser Technology and Photonics", March 20, 2010. CAMP, Manipal University, Manipal, INDIA.

- Participated the annual photonics workshop on "Quantum Optics", February 27-28, 2010, CUSAT, Cochin, INDIA.

- Attended one day discussion meeting on "Recent Advances in Photonics", April 11, 2009. CAMP, Manipal University, Manipal, INDIA.

- Participated the national seminar on "Photonic Polymers: Materials, Devices and Applications", April 3-4, 2008, BITS, Pilani, INDIA.

- Attended two-day national workshop on "Virtual Instrumentation and Data Acquisition (VI & DAQ)" September 2007, National Institute of Technology Karnataka, Mangalore, INDIA.

Sponsored Research

- Development of novel metal doped semiconductor thin films with high optical nonlinearities to protect eye and sensors funded by Vision Group on Science and Technology, Government of Karnataka (Rs.5 Lakhs) (2017-2018, ongoing)

- All Optical Nonlinear Characteristics of Novel materials for Optical Power Limiting Applications funded by Seed Money for Research, TEQIP Phase-II (Rs.0.8 Lakhs) (2016-17, completed)

- Engineering Physics

- Optoelectronic Devices

- Advanced Materials Technology

- Program committee member, 10th ISSS national conference - 2019.

- Coordinator, FAER-Technology Barrier Reduction Program (TBRP) - 2017 & 2018

- Chairman, Discipline committee, KSCST-SPP - 2017

- Chairman and member of BOS, BOE, DUGC & DAAB

- Faculty advisor

- Member, Anti Ragging Squad committee

- Sessional Coordinator - First year, 2016-17

- ISO internal auditor - 2015-16, 2016-17 , 2017-18, 2018-19 and 2019-2020

- Member, Hostel visiting team - 2016-17, 2017-18, 2018-19 and 2019-2020

- Member, Discipline committee, Tech-Nidarshan

- Member, Discipline committee, Anandotsava

- Member, College Magazine committee - 2015-16

- Coordinator, Two day workshop on 'Recent Advances in Optoelectronic Materials & Devices' - 2014

- Editorial Assistant, NMAMIT Annual Research Journal - 2014

Dr. SHOBHA R PRABHU

- Designation Associate Professor

- Email shobha@nitte.edu.in

- Contact No.

- Joining date 19-11-2007

- Ph.D-Manipal Academy of Higher Education (MAHE), Manipal–November 2018

- M.Sc. - Mangalore University, Mnagalore-1999

- B.Sc. - Mangalore University -1997

- January 2000 - June 2001: Lecturer,Dandathirtha PU College, Kaup.

- June 2001 – July2002: Lecturer, Poornaprajna College, Udupi.

- August 2002 - November 2007: Lecturer, Dr. NSAM PU College, Nitte.

- November 2007 - February 2015: Lecturer, NMAM Institute of Technology, Nitte.

- February 2015 - December 2019: Assistant Professor Gd III, NMAM Institute of Technology, Nitte.

- July 2019 - July 2024 Head of the Department, dept. of Physics, NMAMIT, Nitte.

- January 2020 - Associate Professor, NMAM Institute of Technology, Nitte.

- Crystal growth and characterization

- Lasers and Nonlinear optics

- Head of the Department

- Chairman and member of BOS, BOE, DUGC & DAAB

- Life member of Optical Society of India (OSI)

- Life Member of Indian Society for Technical Education (ISTE)

- Life Member of Indian Society of Systems for Science & Engineering (ISSE)

- Life member of Institute for Smart Structures and Systems (ISSS)

Journal publications

- Shobha R. Prabhu, V. Upadhyaya*, A. Jayarama, "Synthesis, Crystal structure and Hirshfeld surface analysis of a novel chalcone derivative: (2E)-3-(2,3-dimethoxyphenyl)-1-(3-nitrophenyl)prop-2-en-1-one", Chemical Data Collections, Vol. 11-12, pp. 199-210, (2017).

- Shobha R Prabhu, A Jayarama, K Chandrasekharan, V Upadhyaya, Seik Weng Ng, "Synthesis, growth, structural characterization, Hirshfeld analysis and nonlinear optical studies of a methyl substituted chalcone", Journal of Molecular Structure, 1136, 244-252, (2017).

- Shobha R. Prabhu, A. Jayarama, V. Upadhyaya, K. Subrahmanya Bhat &Seik Weng Ng, "Structure and Characterization of a Novel Chalcone Crystal Having Nitro as an Acceptor Group",Molecular Crystals and Liquid Crystals, 607:1, 200-214, (2015).

Conferences

- National conference on Condensed Matter Physics and Applications (Cmpa 2016)" held at Manipal Institute of Technology on May 23-24, 2016.

- "National conference on Recent Trends in Chemical Sciences (NCRTCS-2016 )" held at Manipal Institute of Technology on January 11-12, 2016.

- "National conference on Condensed Matter Physics and Applications (Cmpa 2015)" held at Manipal Institute of Technology on March 27-28, 2015.

- "National conference on Condensed Matter Physics and Applications (Cmpa 2013)" held at Manipal Institute of Technology on December 27-28th 2013.

- . "National conference on Smart Materials & Technology for Emerging Electronics" held at Mangalore Institute of Technology & Engineering, Moodbidri, on March 8-9th 2013.

- "National conference on Condensed Matter Physics and Applications (Cmpa 2012)" held at Manipal Institute of Technology on December 27-28th 2012.

Papers Presented in National Conferences:

- Shobha R. Prabhu, V. Upadhyaya, A. Jayarama, "Synthesis and third order nonlinear optical studies of (2E)-3-(2-methylphenyl)-1-(3-nitrophenyl)prop-2-en-1-one using cw laser" in the "6th National Conference on Condensed Matter Physics and Applications (Cmpa 2018)" held at Manipal Institute of Technology, Manipal on 10-11, September 2018.

- Shobha R. Prabhu, V. Upadhyaya, A. Jayarama, Seik Weng Ng, "Synthesis and characterization of a novel organic nonlinear optical material" in the "5th National Conference on Condensed Matter Physics and Applications (Cmpa 2017)" held at Manipal Institute of Technology, Manipal on 22-23rd September 2017.

- Shobha R. Prabhu, V. Upadhyaya, A. Jayarama, "Synthesis, Growth and Structural Characterization of a Novel Chalcone Compound" in the "4th National Conference on Condensed Matter Physics and Applications (Cmpa 2016)" held at Manipal Institute of Technology, Manipal on 23-24th May 2016.

- Shobha R. Prabhu, V. Upadhyaya, A. Jayarama, "Synthesis, Crystal Growth and Characterization of a Novel Chalcone Compound", National Conference on Recent Trends in Chemical Sciences (NCRTCS - 2016), 11-12 January, 2016.

- Shobha R. Prabhu, V. Upadhyaya, A. Jayarama, Seik Weng Ng "Synthesis, Crystal Growth and Characterization of a Novel Chalcone Crystal" in the "National Conference on Condensed Matter Physics and Applications" held at Manipal Institute of Technology, Manipal, 27-28th March 2015.

- Shobha R. Prabhu, V. Upadhyaya, A. Jayarama, Seik Weng Ng,"Synthesis, Growth and Characterization of a new π - conjugated Organic NLO Material: (2E)-3-(2-methylphenyl)-1-(4-nitrophenyl) prop-2-en-1-one",National conference on Condensed Matter Physics and Applications, Manipal Institute of Technology, Manipal, December 27-28th, 2013.

Workshops/seminars attended:

- Five days faculty workshop on "Accreditation and Leadership"organized by Internal Quality Assurance Cell (IQAC) of NMAM Institute of Technology, Nitte during 23rd-28th December 2019.

- Science Academies' Lecture Workshop on "Computational Methods in Physics and Chemistry" (Supported by IASc, INSA and NASI), A Three days Lecture Workshop, from 06-08 August 2018, organised by Manipal Academy of Higher Education, Manipal.

- One Day workshop on "Advanced materials chemistry for science and engineering", organised by the Department of Chemistry, NMAMIT, Nitte, on 26th July 2018.

- Participated in the workshop on "New Model Curriculum for First Year B.E./B.Tech-CBCS Detailed Syllabus (2018-19) as per Outcome-Based Education (OBE) format including Course Outcomes (CO) and Bloom's Taxonomy" under TEQUIP-1.3 for the course under Physics board held on 19-05-2018 at SCEM, Mangaluru, organized by VTU, Belagavi.

- One day Symposium on "Recent Advances in Photonics", organised by Department of Atomic and Molecular Physics, MIT, Manipal University, Manipal, on November 13, 2017.

- One day workshop on"Advanced Chemical Research for Engineering Applications", organised bythe Department of Chemistry, NMAMIT, Nitte, on 20th July 2017.

- National Workshop on "Recent Trends in Clean Energy -Fundamentals to Applications [RTCE-2017]" Organized by Dr.T.M.A. Pai Endowment Chair in Clean Energy and Department of Physics, Manipal Institute of Technology, Manipal University, during May 19-20, 2017.

- Faculty Development Program on "Research Literacy, Academic Writing, E-Resources and Research Quality Indicators" organized jointly by the Research and Development Cell and Library and Information Centre on 6th February 2017 at NMAMIT Nitte.

- Four day' workshop on "Introduction to Therapeutic Counselling for Engineering Teachers"held at NMAMIT, Nitte from 13th to 16th July 2015.

- A Two Day National Level workshop on "Recent Advances in Optoelectronic Materials and Devices"held on 30th& 31st July2014 at NMAMIT, Nitte.

- Two Day workshop on "Modern Trends in Chemical Research And Their Applications"held on 10th and 11th July 2014 at NMAMIT, Nitte.

- "National Level Workshop on Advanced Materials Research for Device Applications"held at NMAMIT, Nitte on 25th& 26th July 2013.

- Three Day National Workshop on "Research Methodologies & Effective Publication Practices" during 25-27th July 2012, organised by NMAMIT Nitte.

- Two Day workshop for Teaching staff "Personality Plus" on 26-27th March 2012 organized by Nitte University.

- Two Day National Work shop on "Public Awareness programme on Benefits and Risks of Radiation" held at Poornaprajna College, Udupi on 19th&20th of August 2011.

- Three Days "Faculty Empowerment Programme" by I-Point Consulting Services Pvt. Ltd. on 23-25th August 2010, at NMAMIT Nitte.

- "Wipro Mission 10X" workshop conducted at NMAM Institute of Technology, Nitte from 14th to 18th June 2010.

- One Day Symposium on "Laser Technology & Photonics" on March 20th , 2010, at Centre for Atomic and Molecular Physics, Manipal University, Manipal.

- MHRD sponsored "Summer School on Advances in Engineering Physics", during July 6th- 11th 2009, at NITK, Surathkal.

- "State level conference on Teaching Quality Enhancement" on 8th - 9th March 2007, at Dr. NSAM First Grade College, Nitte.

- "National workshop on Nanomaterials and Devices", held at NMAMIT Nitte on 16th - 17thAugust 2007.

- "National workshop on Electronics &Optical materials &Devices", held at NMAMIT Nitte on 24th and 25th August 2006.

- Engineering Physics

- Engineering Physics Lab

- Optoelectronic Devices (Open Elective)

- Registration committee head for the 10th ISSS National Conference on "Micro and Smart Systems", jointly organized by NMAMIT and ISSS Bengaluru held on October 21 - 23 2019 at NMAMIT Nitte.

- Stream coordinator for the Eighth International Conference on Emerging Trends in Engineering (ICETE'18) held at NMAMIT, Nitte during 14th-15th May 2018.

- Registration committee head, Two-day workshop on 'Recent Advances in Optoelectronic Materials & Devices' - 2014

- Registration committee head for the Two-day workshop on "Advanced Materials Research for Device Applications" organized by Departments of Physics and Chemistry, NMAMIT during 25 - 26, July 2013.

- Member, Discipline committee, Incredia-2020

Dr. SATHYAJITH K T

- Designation Associate Professor

- Email sathyajith.kt@nitte.edu.in

- Contact No.

- Joining date 01-01-2021

- M.Sc.

- Ph.D (Physics)

ADDITIONAL DEGREE/DIPLOMA

- Certificate in Java programming – NIIT, 2000

- Certificate in C++ programming on Linux Platform – NIIT, 2000

- Post graduate diploma in Computer Application – St Aloysius College, 1998

- 1997-1999 : Lecturer, St.Aloysius College, Mangalore, Karnataka.

- 1999-2002: Lecturer, Alvas College, Moodbidri, Karnataka.

- 2002-2003: Lecturer, PES College, Bangalore, Karnataka.

- 2003-2004: Lecturer, Surana College, Bangalore, Karnataka.

- 2004-2008 : JRF, BRNS Project, Department of Physics, Bangalore University, Bangalore, Karnataka.

- 2008-2011: Guest Faculty, Department of Physics, Bangalore University, Karnataka.

- 2011-2019: Assistant Professor, Department of Sciences, Amrita School of Engineering, Amrita University, Coimbatore, Tamilnadu.

- Ion Trapping

- Atomic Physics and Medical Instruments.

- Taking classes for I year B.E. students

- Any other responsibility entrusted by the department

- Indian Society for Atomic and Molecular Physics, ISAMP, India (Life Member)

- Member of DeutschenPhysikalischen Gesellschaft(DPG), Germany (German Physical Society), Germany.

- Member, Storage Particle Research Collaboration (SPARC), GSI, Germany.

- K.T.Satyajit, B.M. Dyavappa, Sharath Ananthamurthy, Experiments with a non-neutral electronPlasma in a Quadrupole Penning trap: current work and possibilities, SPARCMeeting, 2014, January 28-29TIFR, Bombay (2014)

- K.T.Satyajit, B.M. Dyavappa, Sharath Ananthamurthy, Durgesh Datar,Dependence of the storage time ofa non-neutral electron plasma on the magnetic field in a Penning trap, Topical Conference on Atomic Processes in Plasmas (ISAMP-TC 2013), November 18-20, IPR, Gandhinagar, India (2013)

- K.T.Satyajit, Pushpa M. Rao, Sharath Ananthamurthy, Storage instabilities of a weakly coupled Electron plasma in a Penning trap, National Conference DAE BRNS Symposium on AtomicMolecular and Optical Physics 10-13, February IUAC, New Delhi (2009).

- K.T Satyajit, Sharath Ananthamurthy Non-destructive Detection of Electrons in a Penning Trap, National Conference (XVI NCAMP 2007), January 8-11, TIFR, Mumbai (2007)

- K.T.Satyajit, B.M. Dyavappa, Sharath Ananthamurthy, Storage time and axial velocity distribution of electrons in a quadrupole Penning trap, WHICH International Workshop, TIFR Mumbai, 28-31 (March 2012).

- K.T.Satyajit and Sharath Ananthamurthy, Measurement of electron storage time and its dependence on space charge and magnetic field in a quadrupole Penning trap, International Conference on Cold Atoms and Ions, Kolkata 18th-21stJanuary (2010)

- K.T Satyajit, Sharath Ananthamurthy Trapping and Detection of electrons in a Penning Trap, International Conference (ICLAN), November 30-December 1-2, Kolkata University, Kolkata (2006).

- K.T.Satyajit, Pushpa M. Rao, Sharath Ananthamurthy, Effect of collisions on stability of ions in a Penning Trap International Conference (CDAMOP 2006), March 21-23, Delhi University, Delhi (2006).

- K.T Satyajit, Sharath Ananthamurthy, Suresh D, T.E.Kanakavalli, Sharath Ananthamurthy, Low-Cost Scanning Fabry Perot Interferometer for Student Laboratory, PPhotonics 2004, Seventh International Conference on Optoelectronics, FiberOptics, and Photonics, Cochin University of Science and Technology, Cochin, India, December 9-11, (2004).

- Tani Chaitanya, Sahana S, Sangeetha Sasidharan and Satyajit K.T, "An Electron Beam Device for Low Energy Electron Beam", AISAMP, TIFR, Mumbai, December 2018

- Swaroop Surya I., Sangeetha Sasidharan, Tani Chaitanya, Sahana S. and Satyajit K.T., Trapping and Detection of Electrons in a Cylindrical Penning Trap, AISAMP, TIFR, Mumbai December 2018

- Satyajith KT et al. Loading Detection and Number Estimation of an Electron Plasma in a Penning Trap, Plasma Science and Technology 11, no. 5 (10, 2009): 521-528.

- K. T Satyajith et al. Motional resonances of electrons in a quadrupole Penning Trap, Asian Journal of Physics Vol. 20, No.2 &3 (2011) 281-290

- Manoj Joshi, K. T Satyajith, Pushpa M.Rao, Influence of a geometrical perturbation on the ion dynamics, in a 3D Paul trap, NIM A, 2015

- Datar, Durgesh, B M, Dyavappa, B L, Mahesh; Satyajith, K T, Ananthamurthy Sharath, Energy distribution of electrons under axial motion in a quadrupole Penning trap, Canadian Journal of Physics Volume 94, Number 11, November 2016

- Engineering Physics

- Electrical Engineering Materials

- Electricity and Magnetism

- Electrodynamics

- Advanced Electrodynamics

- Atomic Physics

- Error Analysis

- Experimental Techniques

- Optics

- Computer Programming

- Digital Electronics

- Mechanics

- Quantum Mechanics

- Biophysics

- Medical Electronics

- Title of the project "Development of low energy electron beam". Internal Grant of 8 lakh Rupees from Amrita University Coimbatore.

- An electron beam setup of energy up to 100 eV was developed.

- Short term visiting Fellowship, TIFR, Mumbai ( November 2009 to January 2010 ) to carry out experimental work in ion trapping with Europium ions (carried out at Spectroscopy division BARC Mumbai).

- Recipient of Best thesis award-National Conference DAE BRNS Symposium on Atomic Molecular and Optical Physics 2011, Karnataka University, Dharwad; National level award by Indian Association of Physics.

- Visiting Scientist to carry out experiments on highly charged ions at Heavy Ion Collider, GSI, Germany since June 13th, 2015.

Innovating teaching programs conducted

- A unique method of teaching geometry, through paper folding was developed and 9th standard kids from the Joyland School, Bolar, Mangalore, was taught, during November 2019

- Physics was taught completely based on ahands on approach by building a toy car, incorporating knowledge of Mechanics, optics and current electricity for children with language learning difficulties at the Anirveda centre for Psychological well being, Mangalore, during October -November 2019.

Talks and Interviews

- "Has the future arrived too early ?" (Invited talk), "Industry 4.0", National Conference, , Punjalakatte Government Junior College, 25th February 2020.

- "A few experiments in Penning and Paul trap" (Seminar), Atomic Physics Seminar, GSI, Germany, June 2015,

- "Frequency shifts in Penning traps", (Invited talk),National Conference on Atomic and Molecular Physics, Indian Institute of Space Science and Technology, Thiruvananthapuram, 12th December 2014

- "Motional Resonances in Penning trap"(Invited talk),SPARC Meeting, TIFR, Mumbai, 29th January 2014.

- "Light and life"(Public Lecture),Mysore Science Forum, Mysore, 26th October, 2014.

- "Making ions dance to your tune " (Public lecture), Seminar Series Public Lecture Series, National College, Jayanagar,Bangalore, May 2010.

- "Physics of atoms"(Invited talk), Jain College, Bangalore, January 26, 2009

- Fusion and Nuclear energy" (TV interview series), Kasturi channel, Bangalore, September 2008.

- "To see the Universe in an atom", Taralabalu Institute, Davanegere, June 2008.

- Physics of Tsunami waves, Talk, Department Of Physics, Bangalore University, August 14, 2004.

Organizations and events

- Co-founded RISER (Regional Institute for Science Education and Research), a non-profit organisation for promotion of science education among rural students and conducted the following workshops.

- Quantum theory of Angular momentum" , two series of lectures, 7 days each by eminent Physicist, Professor Ramachandran on ", at KLE College Bangalore and IISc Bangalore, during July 2014, as part of RISER.

- "Quantum Mechanics Decoded", one day Workshop on Quantum Mechanics at Excellent College Moodbidri, January 31st, 2016, as a Part of RISER.

Dr. RAGHAVENDRA BAIRY

- Designation Associate Professor & Head

- Email rbairy@nitte.edu.in

- Contact No.

- Joining date 08-09-2011

- Ph.D. in Physics from Visvesvaraya Technological University (VTU), Belagavi.

- M.Sc. in Electronics from Mangalore University.

- M.Sc. in Physics from Kuvempu University DDE.

- B.Sc. (Physics, Mathematics and Chemistry) from PPC Udupi, Mangalore University.

- Head of the department from August 2024

- Associate Professor in NMAM Institute of Technology, Nitte, from 2023

- Assistant Professor Gd-III in NMAM Institute of Technology, Nitte from January 2020

- Assistant Professor in NMAM Institute of Technology Nitte from June 2014 to December 2020.

- Lecturer in Department of Physics, NMAM Institute of Technology Nitte from September 2011 to May 2014.

- Lecturer in Mother Theresa’s Pre-University College, Shankaranarayana from Aug 2009 to August 2011.

- Lecturer in Department of Electronics, Dr. NSAM First-Grade College, Nitte from June 2006 to July 2009.

- Hardware Verification Engineer in Kamaljeeth Instrumentation and Service Unit (KJISU) Pvt Ltd., Bangalore from June 2005 to May 2006.

- Semiconductor Thin Films

- Nonlinear Optical Materials

- Nanocomposites

- Materials Science.

- ISO Coordinator

- Department Lab Coordinator

- Member: BOS, BOE & DUGC

- Mentor for the 1st Year UG students Internship

- Life Member and coordinator of Institute of Smart Structures and Systems (ISSS).

- Life member of Indian Society of Systems for Science& Engineering (ISSE).

International Journals (Scopus Indexed)

- Raghavendra Bairy*, H Vijeth, SD Kulkarni, MS Murari, UK Bhat, Improvement of third-order NLO properties of vacuum deposited Cd1-xPbxS nanostructured thin films for optoelectronic device applications, Materials Research Bulletin, 161 (2023) 112146. (Q1, Elsevier Publisher) H index - 124, SNIP - 0.963, IF - 5.4, SJR - 0.818. https://doi.org/10.1016/j.materresbull.2023.112146.

- D Haleshappa, Raghavendra Bairy, Shridevi, S.N. Kakathkar, Vijeth H, Neelamma Gummagol, "Thiophene-centered PMMA unified thin films with electrical, photoluminescence, and third-order nonlinear optical potentials for optoelectronic applications", Materials Today Communications, 35 (2023) 106052. (Q2, Elsevier Publisher) H index - 42, IF - 3.662, SJR - 0.623. https://doi.org/10.1016/j.mtcomm.2023.106052

- Raghavendra Bairy, Ananthakrishna Somayaji, Narasimha Marakala, Udaya Devadiga, M Rajesh, John Chuol Wal, Role of Cobalt Doping on the Physical Properties of CdO Nanocrystalline Thin Films for Optoelectronic Applications, Advances in Materials Science and Engineering, 2022 | Article ID 8454811 (Q2, Hindawi Publisher) H index - 59, IF - 2.098, SJR - 0.46. https://doi.org/10.1155/2022/8454811

- Charishma Shetty, V Veena Devi Shastrimath, Raghavendra Bairy, Tuning the structural, morphological and optical properties of Sr-doped BFO thin films, Phase Transitions, 95 (3) (2022) 202-211 (Q3, Taylor & Francis), H index - 48, IF - 1.71, SJR - 0.31. https://doi.org/10.1080/01411594.2022.2032056.

- Raghavendra Bairy*, K. N. Narasimhamurthy, "Efect of annealing temperature on optimizing the structural, linear-nonlinear optical properties of Cd1‑xZnxS nanocrystalline thin flms", Optical and Quantum Electronics, 53 (2021) 579. (Q2, Springer Nature) H index - 68, IF - 2.084, SJR - 0.396. https://doi.org/10.1007/s11082-021-03215-0.

- Raghavendra Bairy*, D. Haleshappa, M.S. Murari, "The structural, linear and nonlinear optical properties of high quality Zn1‑xPbxO nanostructured thin flms for optoelectronic device applications", Applied Physics B, 127 (2021) 113. (Q2, Springer Nature) H index - 139, IF - 2.1, SJR - 0.45. https://doi.org/10.1007/s00340-021-07659-w.

- Laxminarayana Kamath, Anthoni Praveen Menezesb∗, Raghavendra Bairy, Shashi Kumar Kumaraswamy, A. Jayarama, "Hirshfeld surface analysis, enrichment ratio, energy frameworks and third-order nonlinear optical studies of a hydrazone derivative for optical limiting applications", Journal of Molecular Structure, 1245 (2021) 131019. (Q2, Elsevier Publisher) H index - 117, IF - 3.841, SJR - 0.48. https://doi.org/10.1016/j.molstruc.2021.131019

- Raghavendra Bairy**, A. Jayarama*, Suresh D. Kulkarni, M.S. Murari, H. Vijeth, "Improved nonlinear optical absorption mechanism and susceptibility (χ(3)) of CdS nanostructured thin films: Role of zinc doping". Materials Science in Semiconductor Processing 121 (2021) 105400. (Q1, Elsevier Publisher) H index - 77, IF - 4.644, SJR - 0.69. https://doi.org/10.1016/j.mssp.2020.105400.

- Sandesh kumar Rai, Rajesh Rai, Raghavendra Bairy, H Vijeth, A Jayarama, "Effect of Mg on structural, morphological and optical properties of Mg-doped V2O5 nanostructures", Materials Today: Proceedings, 35 (2021) 396-404 (Q3, Elsevier Publisher) H index - 69, IF - 1.4, SJR - 0.45. https://doi.org/10.1016/j.matpr.2021.01.304.

- Haleshappa D∗, Raghavendra Bairy, Jayarama A, Ching KhengQuah, Huey Chong K wong, Parutagouda Shankaragouda Patil, "Structural, photoluminescence, physical, optical limiting, and hirshfeld Surface analysis of polymorphic chlorophenyl organic chalcone derivativefor optoelectronicapplications". Journal of Molecular Structure, 1232 (2021) 130053. (Q2, Elsevier Publisher). H index - 117, IF - 3.841, SJR - 0.48. https://doi.org/10.1016/j.molstruc.2021.130053

- Raghavendra Bairy*, A Jayarama, MS Murari, "Structural, linear and nonlinear optical properties of Cd1− xAlxS semiconductor nanostructures: Influence of film thickness", Materials Today: Proceedings, 35 (2021) 483-488. (Q3, Elsevier Publisher) H index - 69, IF - 1.4, SJR - 0.45. https://doi.org/10.1016/j.matpr.2020.03.063.

- BS Nagaraja, SC Gurumurthy, Raghavendra Bairy, Koduri Ramam, K Bindu, Ashok Rao, A systematic investigation on structural, electrical, linear and nonlinear optical properties of Zn: CdO thin films for optoelectronic applications, Optical Materials, 122 (2021) 111669 (Q1, Elsevier Publisher) H index - 113, IF - 3.754, SJR - 0.61. https://doi.org/10.1016/j.optmat.2021.111669.

- L Kamath, Raghavendra Bairy*, A Jayarama, B Narayana, NB Gummagol, PS Patil, "Preparation, characterization and study on the nonlinear optical parameters of novel biphenyl-4-carbohydrazide derivative", Materials Today: Proceedings, 35 (2021) 478-482 (Q3, Elsevier Publisher) H index - 69, IF - 1.4, SJR - 0.45. https://doi.org/10.1016/j.matpr.2020.03.062

- Charishma, VVD Shastrimath, Raghavendra Bairy, MS Murari, A Jayarama, R Pinto, "Structural, morphological and optical properties of barium doped bismuth ferrite thin films deposited by spray pyrolysis", Materials Today: Proceedings, 35 (2021) 440-444 (Q3, Elsevier Publisher). H index - 69, IF - 1.4, SJR - 0.45. https://doi.org/10.1016/j.matpr.2020.02.950

- SK Rai, R Rai, Raghavendra Bairy, MS Murari, A Jayarama, R Pinto, "Role of Zn in tuning the structural, morphological and optical properties of V2O5 nanostructures deposited by spray pyrolysis", Materials Today: Proceedings, 35 (2021) 469-473 (Q3, Elsevier Publisher). H index - 69, IF - 1.4, SJR - 0.45. https://doi.org/10.1016/j.matpr.2020.03.028

- M Banuprakash, B Abhishek, H Acharya, Raghavendra Bairy, S Bhat, H Vijeth, MS Murari, A Jayarama, Richard Pinto, "Structural, linear and nonlinear optical characterization of Ni and Al Co-Doped CdO semiconductor nanostructures for nonlinear optical device applications", Materials Today: Proceedings, 35 (2021) 396-404 (Q3, Elsevier Publisher) H index - 69, IF - 1.4, SJR - 0.45. https://doi.org/10.1016/j.matpr.2020.02.766

- Raghavendra Bairy*, A Jayarama, MS Murari, "Significant effect of film thickness on morphology and third-order optical nonlinearities of Cd1−xZnxO semiconductor nanostructures for optoelectronics". Applied Physics A, 126 (8) (2020) 1-15. (Q2, Springer Nature) H index - 158, IF - 2.983, SJR - 0.45. https://doi.org/10.1007/s00339-020-03771-4.

- Raghavendra Bairy*, Suresh D. Kulkarni, M.S. Murari, "Effect of Al doping on photoluminescence and laser stimulated nonlinear optical features of CdO nanostructures for optoelectronic device applications". Optics and Laser Technology, 126 (2020) 106113. (Q1, Elsevier Publisher, 2020) H index - 96, IF - 2.983, SJR - 4.93. https://doi.org/10.1016/j.optlastec.2020.106113

- Raghavendra Bairy*, Suresh D. Kulkarni, M.S. Murari, K. N. Narasimhamurthy, "An investigation of third‑ order nonlinear optical and limiting properties of spray pyrolysis- deposited Co:CdS nanostructures for optoelectronics", Applied Physics A, 126 (5), (2020) 380. (Q2, Springer Nature) H index - 158, IF - 2.983, SJR - 0.45. https://doi.org/10.1007/s00339-020-03549-8.

- Raghavendra Bairy*, Parutagouda shankaragouda Patil, Shivaraj R. Maidur, Vijeth H., Murari M. S. and Udaya Bhat K., "The role of cobalt doping in tuning the band gap, surface morphology and third-order optical nonlinearities of ZnO nanostructures for NLO device applications". RSC Advances, 9 (2019) 22302-22312 (Q1, Royal Society of Chemistry) H index - 189, IF - 4.036, SJR - 0.68. https://doi:10.1039/c9ra03006a8.

- Gananatha Shetty B, Vincent Crasta∗, Rithin Kumar N B, Rajesh K, Raghavendra Bairy, Parutagouda Shankaragouda Patil, "Promising PVA/TiO2, CuO filled nanocomposites for electrical and third order nonlinear optical applications", Optical Materials, 95, (2019) 109218. (Q1, Elsevier Publisher) H index - 113, IF - 3.754, SJR - 0.61. https://doi.org/10.1016/j.optmat.2019.109218.

- Raghavendra Bairy, Jayarama A*, Suresh D Kulkarni, Murari M S and Vijeth H, "Role of Zn in tuning the band gap, surface morphology, photoluminescence and optical nonlinearities of CdO nanostructures for photonic device applications, Material Research Express 6 (09) (2019) 6447. (Q2, IOP Publisher) H index - 52, IF - 2.025, SJR - 0.4. https://doi.org/10.1088/2053-1591/ab3329

- B Gananatha Shetty, Vincent Crasta, N B Rithin Kumar, K Rajesh and Raghavendra Bairy, "Effect of nano fillers on electrical, mechanical, fluorescent and third-order non- linear optical properties of PVA", Materials Research Express, 6 (7) (2019) 075055. (Q2, IOP Publisher) H index - 52, IF - 2.025, SJR - 0.4. https://doi.org/10.1088/2053-1591/ab17f6.

- Raghavendra Bairy*, A. Jayarama, G. K. Shivakumar, Radhakrisnhan, and K. Udaya Bhat, "Investigation of third-order nonlinear optical properties of nanostructured Ni- doped CdS thin films under continuous wave laser illumination", Journal of Materials Science: Materials in Electronics 30 (2019) 6993-7004. (Q2, Springer nature) H index - 88, IF - 2.779, SJR - 0.5. https://doi.org/10.1007/s10854-019-01017-5.

- Raghavendra Bairy*, Jayarama A, G.K. Shivakumar, Suresh D. Kulkarni, Shivaraj R. Maidur, Parutagouda Shankaragouda Patil, "Effect of Aluminium doping on photoluminescence and third-order nonlinear optical properties of nanostructured CdS thin films for photonic device applications", Physica B: Condensed Matter, 555 (2019) 145-151. (Q2, Elsevier Publisher) H index - 124, IF - 2.988, SJR - 0.47. https://doi.org/10.1088/2053-1591/ab3329

- D. Haleshappa, A. Jayarama, Raghavendra Bairy, Santhosha Acharya, Parutagouda Shankaragouda Patil, "Second and third order nonlinear optical studies of a novel thiophene substituted chalcone derivative", Physica B: Condensed Matter 555 (2019) 125-132. (Q2, Elsevier Publisher) H index - 124, IF - 2.988, SJR - 0.47. https://doi.org/10.1016/j.physb.2018.11.046.

- Raghavendra Bairy*, A. Jayarama, G. K. Shivakumar, P. S. Patil, and K. Udaya Bhat, "Zn doped CdO thin films with enhanced linear and third order nonlinear optical properties for optoelectronic applications", American Institute of Physics, 1943 (1), (2018) 020070 (Q3, Scopus) H index - 80, IF - 1.697, SJR - 0.16. https://doi:/10.1063/1.5029646.

Research papers presented in International/National conferences (selected)

- Raghavendra Bairy has presented a research article on "Linear and nonlinear optical properties of Barium doped BiFeO3 nanocrystalline thin films prepared by spray pyrolysis technique", in the International Conference on Nanoscience and Photonics for Medical Applications (ICNPMA - 2022) organized by Department of Atomic and Molecular Physics (DAMP), MAHE, Manipal, 28- 30 December 2022.

- Raghavendra Bairy*, Suresh D. Kulkarni, presented a research article on "Defect assisted reverse saturable absorption characteristics in Ni-doped CdS nanostructures for optoelectronic device applications", in the International Conference on Advanced Science and Material Applications, (Online) organized by MSRIT Bengaluru, ICASMA - 2020, 3 - 4 September, 2020.

- Raghavendra Bairy, has presented a research article on "Structural, linear and nonlinear optical properties of Cd1− xAlxS semiconductor nanostructures: Influence of film thickness", in the International Conference on Laser Deposition (iCOLD - 2019) organized by AIET Moodabidri in association with IIT Madras during 27 - 29, November 2019.

- Raghavendra Bairy presented a research article on "Effect of Al doping on Photoluminescence and laser stimulated nonlinear optical features of CdO nanostructures for optoelectronic device applications", in the National Conference on Condensed Matter Physics and Applications (CMPA), MIT - MAHE Manipal, 27-28 September, 2019.

- Raghavendra Bairy*, G K Shivakumar, Radhakrishnan K, Jayarama A, Udaya Bhat K, International Conference on Emerging trends in Engineering (ICETE - 2018 at NMAMIT-Nitte, Theme 1:E3S, Allied Engineering (364 -368) May 2018.

- Raghavendra Bairy*, A. Jayarama, G. K. Shivakumar, P. S. Patil, and K. Udaya Bhat, presented a research article on "Zn doped CdO thin films with enhanced linear and third order nonlinear optical properties for optoelectronic applications", at International Conference on Design, Materials & Manufacture (IcDeM - 2018) NITK Surathkal, 29 - 31 January, 2018.

- Raghavendra Bairy*, Jayarama A, P S Patil, Udaya Bhat K, "Cobalt doped ZnO thin films with enhanced linear and third order nonlinear optical properties for optoelectronic applications", International Conference on Recent Advances in Materials Science and Biophysics (RAMSB - 2018), Mangalore University, ISBN 978-93-5291-953-6, 23-25 January, 2018.

Conference/Workshops/FDP/seminars conducted

- As an Organizing Secretary Successfully Conducted 10th ISSS (Institute of Smart Structures and Systems) National Conference at NMAMIT Nitte during 21-23 October, 2019 in asscociation with ISSS - IISc Bengaluru.

- As a Coordinator, successfully conducted Motorola Sponsored Technology Barrier Reduction Program (TBRP), one month training program for rural high school students conducted at NMAMIT, Nitte for two years (April 2013 and April 2014).

- As a Coordinator, successfully conducted two days workshop on "Recent Advances in Optoelectronic Materials and Devices" Organized by Department of Physics, NMAMIT, Nitte held on 30-31 July 2014.

- As a Coordinator, successfully conducted two days workshop on "Advanced Materials Research for Device Applications" organized by Departments of Physics and Chemistry during 25 - 26 July, 2013.

Workshops/FDP/Seminars attended

- Attended a Faculty Development Programme on Mentoring Skills, organized by Staff Development Centre, Nitte (Deemed to be) University, Mangaluru during 21-22 June 2023.

- Successfully completed Coursera Certification Course (an online non credit course) on Assessment in Higher Education : Professional Development for Teachers, authorized by University at Buffalo, 14 June 2023.

- Attended a Faculty Development Programme on Stress Management, organized by Staff Development Centre, Nitte (Deemed to be) University, Mangaluru, during 23-24 March 2023.

- Successfully completed AICTE Training And Learning (ATAL) Academy FDP on Quantum Computing and Quantum Information Technology: New Vertical of Computing Technology, at MANIPAL ACADEMY OF HIGHER EDUCATION, Bengaluru Campus, during 28 Nov to 02 Dec 2022.

- Successfully completed Coursera Certification Course (an online non credit course) on Renewable Energy : Fundamentals and Job Opportunities, authorized by University at Buffalo, 18 December 2022.

- Attended a Faculty Development Programme (online) on "Foremost Frontiers of Material Science", organized by the department of Physics, Sathyabama Institute of Science and Technology, Chennai from 12 - 20 September 2022.

- Participated in a DST sponsored National Workshop on Usage of Sophisticated Instruments Organized by PURSE laboratory Mangalore University during 4 - 9 April, 2022.

- Successfully completed AICTE Training And Learning (ATAL) Academy (Online) FDP on "Photonics" at GURU JAMBHESHWAR UNIVERSITY OF SCIENCE AND TECHNOLOGY, HISAR, 02 - 06 November, 2020.

- Successfully completed AICTE Training And Learning (ATAL) Academy (Online) FDP on "Novel Materials" at Pillai College of Engineering, 05 - 09 October, 2020.

- Successfully completed three Coursera Certification Courses (online) : Nanotechnology and Nanosensors Part 1, Nanotechnology and Nanosensors Part 2 and COVID - 19 contact tracing, August to October 2020.

- Participated in Five Days (online) FDP on "Thin Film Technologies: Fabrication, Characterization and Simulation", organized by RV College of Engineering, Bengaluru, August 3-7, 2020.

- Participated in one-week FDP (online) on "Material Synthesis and Characterization for Device Applications", organized by NMIT Bengaluru, 31 August - 5 September 2020.

- Participated in Five day Faculty Development Workshop on Hands on Training on use of Digital Board & Pedagogical Techniques, From 1 June to 8 June, 2020, organized by NMAMIT Nitte.

- Successfully completed NPTEL online certification course on Solid State Physics, July-Oct 2019.

- Attended workshop on "Advanced Materials Chemistry for science and Engineering" at NMAMIT Nitte on 26 July, 2018.

- Participated in One day workshop on "Introduction to Patents" held at NMAMIT, Nitte 28 July, 2017.

- Attended One day workshop on "Writing an Effective Project Proposal" held on 24 October 2016 at NMAMIT, Nitte.

- Attended Two days National Level workshop on "Nano Science and Technology", held at Alva's Engineering College, Moodabidri on 11 - 12 March, 2016.

- Actively Participated in VTU Sponsored Training on "Latex and Research Methodology" held at NMAM IT, Nitte on 16 - 18, April 2015.

- Attended Two days "ISO 9001:2008 Internal Auditor Training Program" held at NMAM IT, Nitte on 28- 29 December 2015.

- Attended Faculty Padagology Training held at NMAMIT, Nitte 5 - 9 September 2014.

- Attended three days International Winter School on Organic Electronic Materials & Devices (OEMD - 2013) at NITK Surathkal, on 19 - 21 December, 2013.

- Participated in VTU Sponsored workshop on Introduction to Therapeutic counseling for Engineering Teachers at NMAM IT, Nitte on 09-12, July 2012.

Invited Talks

- Delivered an Invited Talk on "Structural, linear and nonlinear optical properties of Cd1−xAlxS semiconductor nanostructures: Influence of film thickness" in an International Conference on Laser Deposition (iCOLD 2019) was held during November 27 - 29, 2019 at Alvas Institute of Engineering & Technology (AIET) Moodabidri in association with IIT Madras.

- Google Scholar : https://scholar.google.com/citations?user=06jwKCIAAAAJ&hl=en

- Scopus Preview: https://www.scopus.com/authid/detail.uri?authorId=57201908152

- Engineering Physics Theory

- Engineering Physics Laboratory

- Nitte (Deemed to be) University, Research Project Funding (NUFR2 grant for Research of Rs.1,75,000/-) project entitled "Studies on optical limiting, photocatalytic and antibacterial properties of BiFeO3-NaNbO3 doped polymer nanocomposite" (2022-24, Ongoing).

- NMAMIT Research Project Funding (Seed Money for Research, TEQIP Phase-II of Rs. 80,000/-) for research project entitled "Development of aluminum doped cadmium sulfide thin film for solar cell applications" (2016-17, completed).

- News item reports published in the various newspapers for two years of various workshops and other college Megha events held at NMAMIT during Jan 2014 - Dec 2015.

- Member in the compendium committee for the international conference - ICETE 2020.

- Coordinator for Laboratory equipment's maintenance in the department from 2011 to till date.

- Conducting extra classes in the hostel for First year NRI or academically weak students.

- Member under the Publicity and Display Committee in the college from 2012 to 2018.

- ISO internal auditor, Institute level from 2016 to till date.

- Member, NET Hostel visiting team - from 2016 to till date.

- Sports coordinator from Basic science department for the Institute sports activities.

- Member in the Institute Amature Radio Club.

- Member of Rotary Club Nitte from 2019 to 2022 and Vice-president in Rotary Club Nitte for the year 2021-22.

- Won medals in State level Master's Athletic meet and participated in National level Master's Athletic meet.

- Member in the college staff cricket team.

- Faculty coordinator for the Nitte Premier League (NPL) cricket tournament.

- Actively Participated in Institute Cultural events.

- Won Gold medals in District, Silver and Bronze medals in State master's Athletic meets and participated in National level Master's Athletic meet held at Hyderabad and Bangalore during 2017 and 2018.

- Participated in Half Marathon held at Mangalore (Nitte Marathon 2016), Manipal and Bramhavara Jan 2015.

- Champion in the College Annual Sport's meet (men's staff section) in the previous 10 years.

Dr. NAGARAJA B S

- Designation Assistant Professor Gd-III

- Email nagarajbs@nitte.edu.in

- Contact No.

- Joining date 02-07-2018

- Ph.D. in Physics from Manipal Academic of Higher Education (Manipal University), Manipal- 2016.

- M.Sc. in Physics from Manipal Academic of Higher Education (Manipal University), Manipal- 2012.

- B.Sc. (Physics, Mathematics & Computer Sci.) from Kuvempu University -2010.

- Assistant Professor in PG – Department of Physics, Vijaya College, Bengaluru, from August 2016 to August 2017.

- Assistant Professor in Presidency University, Bengaluru, from August 2017 to June 2018.

- Assistant Professor Gd-III in N.M.A.M. Institute of Technology from July 2018

- Research Coordinator

- Centralised Data Capturing System (CDCS) Coordinator.

- Member of DUGC

- Assistant-National Service Scheme (NSS) Programme officer (APO).

- Annual member of Indian Society of Systems for Science & Engineering (ISSE)

- B. S. Nagaraja, Ashok Rao, and G.S. Okram, "Effect of rare-earth ionic radii on structural, electrical, magnetic and thermoelectric power properties of REMnO3 (RE=Dy, Gd, Eu and Sm) manganites", Journal of Superconductivity and Novel Magnetism, 31, 2271-2281 (2018).

- Ramesh Chandra Bhatt, Mamatha D.Daivajna, AshokRao, Shyam Prasad K RiyaThomas, B. S. Nagaraja, V. P. S. Awana, C. F. Lin, B.Ramachandran, Y. K. Kuo, Influence of sintering temperature on the electrical and thermal properties of bulk samples of Pr2/3Sr1/3MnO3-δ" " Physica B: Condensed Matter, 545, 141-145 (2018).

- Shyam Prasad K,Ashok Rao,Benedict Christopher,Ruchi Bhardwaj,Nagendra Singh Chauhan, Safdar Abbas Malik, Ngo Van Nong, B. S. Nagaraja, Riya Thomas, "Tuning the thermoelectric properties by manipulating copper in Cu2SnSe3 system", Journal of Alloys and Compounds, 748, 273-280 (2018).

- Benedict Christopher, Ashok Rao, B. S. Nagaraja, K. Shyam Prasad, G. S. OkramGanesh Sanjeev, Vikash Chandra Petwa, Vijay Pal Verma, Jishnu Dwivedi, and P. Poornesh, "Correlation between structural and transport properties of electron beam irradiated PrMnO3 compounds", Solid State Communications, 270, 30-37 (2018).