The Department of Mechanical Engineering at NMAMIT was established in the year 1986, with an initial intake of 40 students. Since then, the department has experienced substantial growth, and currently, the annual graduating strength of undergraduate students is approximately 180. The department offers a master’s degree program in Machine Design with an intake of 18 students. Accredited by the NBA under Tier-1 category, the department is also recognized as an established Research Centre under Nitte Deemed-to-be University. To date, 15 students have successfully completed their PhD, with several part-time and full-time doctoral students currently enrolled. Additionally, the department hosts several centers of excellence. Students benefit from comprehensive development opportunities, facilitated through professional societies, branch associations, and various professional club activities.

Vision

To produce Mechanical engineers of the highest quality who are professionally competent and highly qualified to suit the needs of industries and organizations by promoting excellence in teaching, learning and research.

Mission

The Dept. of Mechanical Engineering is committed to

- Provide high quality education to the students, to fulfill the requirements ofa ‘Global Engineer’

- Constantly strive to improve the teaching-learning methods, in order to deliver good academic programs

- Respond to the fast evolving scientific and technological challengesin a highly competitive world

- Inculcate, ethics, integrity, honesty, credibility, social and environmental consciousness

Mechanical Engineering graduates of the institution shall be able to

- Work in industry, government and research organizations to do research, design, develop, test, evaluate and implement cutting edge engineering solutions to problems encountered in professional practice

- Communicate and perform as an effective engineering professional in both individual and team-based project environments in industrial and research based organizations

- Consider the ethical implications and societal impact of engineering solutions including environment and sustainability

- Continuously improve lifelong learning through active participation in professional & societal development, adapt to new cultures and emerging career opportunities

- PO1: Engineering knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems

- PO2: Problem analysis: Identify, formulate, review research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences

- PO3: Design/development of solutions: Design solutions for complex engineering problems and design system components or processes that meet the specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations

- P04: Conduct investigations of complex problems: Use research-based knowledge and research methods including design of experiments, analysis, and interpretation of data, and synthesis of the information to provide valid conclusions

- PO5: Modern tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modeling to complex engineering activities with an understanding of the limitations

- PO6: The engineer and society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice

- PO7: Environment and sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and the need for sustainable development

- PO8: Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice

- P09: Individual and team work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings

- PO10:Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions

- PO11: Project management and finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments

- PO12: Life-long learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change

- PSO 1: Apply the concepts and principles of design and to develop solutions to real world problems useful to industries and society in general, which are ethically right, economically sound and environmentally sustainable

- PSO2: Apply thermal engineering principles in solving problems related to the domain, to improve efficiency, reduce losses and pollution and effectively harness different forms of renewable sources of energy for the betterment of future generations

- PSO3: Recognize the importance of manufacturing process and its role in industrial development and provide knowledge about the basics and advances to improve productivity

At the end of the program students shall be able to

Alumni Testimonials

INDUSTRY TESTIMONIALS

Greetings from Fronius India !

Year 2018 was prominent in bridging the association with N.M.A.M NITTE ! The sheer passion from NMAM and Fronius on this year lead us towards the inauguration of the “NMAMIT-FRONIUS Centre for Welding Technology”.

This centre of excellence displays the latest technologies, advancement and precision offered to the welding industry. For Fronius is known and accepted as 75 year old Industry leader in its technology across the globe.

Where VTU University has limited the welding subject to few hours. At NMAM the mechanical department has taken it to the next level, setting a new limit. The eminent scholars / faculties are seen actively encouraging the students at this Centre of Excellence in Welding from as early as 1st semester.

Industrial 4.0, robotic welding in conjunction with IOT is here and NMAM is shaping their students to this next generation in welding for the smart factories ! I am confident that this will definitely help our country initiative of ‘Make in India’.

Mr V V Kamath

Managing Director- F

ronius India Private Limited

I have visited NMAMIT’s Department of Mechanical Engineering in August 2017 for the inauguration of National Conference on “Machining of Difficult to Machine Materials: Recent Developments, Issues and Solutions”. I was highly impressed with the self-contained campus located in a serene rural environment with modern facilities and knowledgeable faculty members, empowering students for all-round growth and professional development and equipping them with future skills.

Dr Rajkumar P Singh

Senior Director,

NMAM Institute of Technology Nitte has been and is, one of the Prime Institutions from where Graduate Engineers have joined industry and adapted / contributed very well to the needs of the Industry. Their technical caliber and sincere structured working needs mention. Some of their students have come up to Prime positions in Industry . Technical Seminars ,Society oriented Projects and Hands On Workshops are the standout points of NMAMIT

I have been interacting with NMAMIT close to 5 years. My initial stint was, as a member of the Board of Studies. Industry oriented Knowledge & Skill Development was high on the BOS agenda.

In the year 2017 NMAMIT, started a unique Project. Developing a State of the Art Automobile Workshop. This was to be a Centre of Excellence in Teaching / Training with an Industrial background. A Ashok Leyland Bus Chassis having the contemporary BS4 emission level engine was procured and a dedicated workshop was put up for all the students to upgrade their skills to contemporary levels. NMAMIT is a pioneer in this

I Wish NMAMIT All the Best in all their future endeavors.

Mr C Prakas

Training & Development

Facilities

Computer Aided Engineering Graphics

This laboratory is used by first year students of chemistry cycle

Read More

Engineering Skill Development Lab

Basic engineering skills like cutting, making joints etc are taught here.

Read More

Machine Shop

Workshop which consists of different types of machine tools like Lathe, shaper, milling

Read More

Foundry, Forging and Welding

In this lab experiments are conducted to evaluate the performance of Pelton turbine.

Read More

Material Testing Laboratory

Laboratory is equipped with instruments such as Universal testing,

Read More

Fluid Machinery Lab

In this lab experiments are conducted to evaluate the performance of Pelton turbine

Read More

Metrology and Measurements Lab

Engineering metrology is a very important subject for mechanical engineers.

Read More

Dynamics Lab

Dynamics and vibrations are integral part of understanding many physical systems

Read More

Heat and Mass Transfer lab

In this lab experiments are conducted in all the three modes of heat transfer..

Read More

Active Learning

Department implements active learning laboratory for Industrial Robotics course.

Read MoreFor any information regarding the admissions,mail us at: info@nitte.edu.in

Faculty

Research

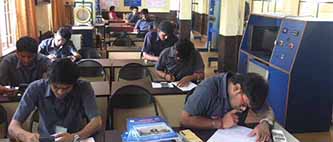

Centre for Condition Monitoring

The centre works in the areas of tool condition monitoring, vibration-based condition monitoring, artificial neural network-based modelling and use of wavelet transform for signal processing. This centre was established in the year 2008 with a funding of Rs. 6.5 Lakhs from VTU under Research Grant Scheme.

Centre for Advanced Machining Research

The centre works in the area of high-speed machining studies, tool wear measurement and evaluation, vibration data acquisition and surface roughness evaluation. This centre was established in the year 2013 with funding of Rs. 17.4 Lakhs from AICTE under Research Promotion Scheme and Rs. 0.15 Lakhs from IE(I) under Grant for R&D. The building space of the centre is 16 X16 sq.ft.

Centre for Alternative Fuel Research

Research is focused on performance enhancement and reduction of emissions from I.C. Engines consuming alternative fuels.

The experimentation on performance characteristic, P-θ diagram and heat release data are conducted on:

- Computerized 4 stroke fixed compression ratio diesel / dual fuel engine

- Computerized 4 stroke variable compression ratio diesel / dual fuel engine

- Computerized 4 stroke twin spark plug petrol engine

Center for Advanced Casting Research

Advanced casting research lab was established in January 2020 to facilitate non-ferrous casting research of academia and industry. In the short span of three years of its establishment the centre has supported several industries in product development and testing. In this regard, the centre has successfully executed projects of flux manufacturing Industry, alloy whee The centre is equipped with state of the art facilities required for Design, simulation and casting studies of non-ferrous metals and alloys.

Facilities

| Equipemnt | Make | >Application |

|---|---|---|

| High Temperature furnace 1300 C | Beneka heating solutions | Casting and heat treatment applications |

| Low temperature furnace 950 C | Beneka heating solutions | Casting and heat treatment applications |

| Rotary Degassing set-up | Gas degassing | |

| Data acquisition system -6210 | National Instruments | Cooling curve analysis |

| Reduced pressure testing set-up | RPT of aluminium alloys | |

| K-mold | Inclusion analysis | |

| Z-Cast simulation software | Dhio-Engineering | Casting simulations |

| Bottom pouring metal finger mould | Tensile & Fatigue sample castings |

NITTE- WIPRO3D Centre of Excellence (CoE) in Digital Manufacturing

The Center of Excellence in Digital Manufacturing is poised to revolutionize the landscape of additive manufacturing, providing a cutting-edge platform for research, collaboration, and skill development. Equipped with state-of-the-art facilities and cutting-edge technology, the center aims to push the boundaries of innovation in digital manufacturing processes and techniques. The center currently has two advanced machines: the Wipro3D Fused Deposition Modelling F300-2 and the Digital Lithography Processing ELEGOO Mercury Plus. These machines represent the latest advancements in digital manufacturing technology and will serve as essential tools for research and development within the center. The establishment of the NITTE-WIPRO3D Center of Excellence in Digital Manufacturing underscores the commitment of both institutions to fostering innovation, research, and collaboration in the field of digital manufacturing. It marks a significant milestone in the journey towards leveraging technology to drive economic growth and societal development.

Facilities

| Equipemnt | Make | >Application |

|---|---|---|

| FFF 3D Printer | Wipro 3D | Polymer, Polymer composite 3D printing (Engineering & Biological applications) |

| DLP printer | Wipro 3D | Polto polymer resin for dental, jewellery, engineering and biological applications |

| UV curing | Wipro 3D | Photopolymer curing |

NMAMIT-FRONIUS Center for welding technology (CWT)

The NMAMIT-FRONIUS Center for Welding Technology (CWT) at NMAMIT, Nitte, in collaboration with the Indian Welding Society (IWS) and M/s. Fronius India Pvt. Ltd., has been actively engaged in advancing research and providing training to both students and faculty members in the field of welding. Over time, the center has successfully conducted numerous skills training programs, featuring renowned experts from IWS and the Welding Research Institute, benefiting students pursuing ITI and B. Tech courses, teaching staff, and industry professionals alike.

CWT also hosts an IWS student chapter, providing students with insights into the latest developments in welding technology. Furthermore, the faculty members affiliated with CWT maintain active communication with nearby industries, offering solutions to their welding-related challenges. In this process, the center has undertaken various consultancy projects. CWT has successfully executed funded projects worth 22.5 lakh from the Science and Engineering Research Board (SERB) and the AICTE.

Facilities/Equipments

| Equipemnt | Make | >Application |

|---|---|---|

| Metallurgical Microscope- DM750 | Leica | Metal samples |

| Disc Polisher | Chennai Metco | Metal samples |

| Stereo Microscope | Leica | Metal samples |

| Virtual Welding machine | Fronius International | Skill training of Arc welding process |

| GMAW machine TPSi 320i | Fronius International | MIG welding of mild steel, stainless steel, Aluminium alloys, Nickel aluminium copper alloy wires |

| GMAW Transteel 2600 | Fronius International | MIG welding of mild steel and Stainless steel |

| GTAW Magic Wave (AC/DC) | Fronius International | TIG welding of mild steel, stainless steel, Aluminium alloys, Nickel aluminium copper alloy wires |

| GTAW TransTiG 1750 | Fronius International | TIG welding of mild steel and Stainless steel |

| SMAW Trans pocket 180 | Fronius International | Stick welding applications |

| Four axis special purpose machine with PLC controller | Custom-built | Wire arc additive manufacturing applications |

| 5 axis cantilever type special purpose machine with CNC controller | In-house built | Wire arc additive manufacturing applications |

| Infrared Thermal Imager (400-1800C) | Micro epsilon | High temperature Thermal imaging applications |

| Ultrasound testing machine EPOCH 4 E | Olympus | Non-destructive testing and corrosion analysis |

Research Grants

| Sl.No. | Title of the Project | Funding Agency | Grant Received(Rs.) | Date Sanctioned | Duration | Status | Principal Investigator |

|---|---|---|---|---|---|---|---|

| 1 | Creation of Laboratory for environmental monitoring | AICTE, MODROBS | 11,13,334 | 1 MArch 2020 | 2 Years | Ongoing | Dr. Shashikanth Karinka |

| 2 | Effect of friction stir welding process parameters on the microstructure and mechanical properties of ultrafine grained titanium elements | SERB | 18,30,000 | 21 November 2019 | 3 years | On going | Mr. Rajath N Rao |

| 3 | Surface Integrity studies during milling of magnesium aluminium alloys used in aerospace applications for improved functional performance | Aeronautics R&D Board.(DRDO) | 10,00,000 | 16 May 2019 | 3 Years | Ongoing | Dr. Srinivasa Pai P |

| 4 | Temperature measurement device for evaluating temperature changes in the gingival sulcus and correlating it to gingival disease. | Nitte University –NMAMIT (Joint) | 56,000 | 9 March 2018 | 0.6 Years | Completed | Dr. Shashikantha Karinka |

| 5 | Redesign and development of multipurpose power tiller for crop production- Special reference to paddy | University of Agriculture and Horticultural Research station, Brahmavara | 10,00,000 | 18 January 2018 | 1 Year | Ongoing | Dr. D K Shreekantha Dr. Shashikantha Karinka |

| 6 | Design, fabrication and testing of a solar stove using reflectors for domestic purpose | NID Ahmadabad- MSME Scheme, GoI | 2,01,000 | 16 January 2018 | 1 Year | Completed | Dr. Shashikantha Karinka |

| 7 | Design, development and testing of pullback toy car mechanism | NID Ahmadabad- MSME Scheme, GoI | 2,00,000 | 27 December 2017 | 1 Year | Completed | Dr. Shashikantha Karinka |

| 8 | Design And Development of Mini Hydraulic Drive System for Robotic Applications | AICTE, New Delhi (RPS) | 10,17,647 | 4 August 2017 | 3 Years | On Going | Dr. Muralidhara |

| 9 | Tool Based Micromachining Research | Management & KCTU, Bangalore | 77,28,000 | 19 July 2017 | 2 Years | Ongoing | Dr. Muralidhara |

| 10 | Machinebility studies in niti shape memory alloys. | Management | 5,00,000 | 28 June 2017 | 3 Years | Ongoing | Dr. Srinivasa Pai P – PI, Mr. Grynel D’Mello– Co-PI |

| 11 | Design and development of piezoactuator based inchworm drive with macro displacement range and sub micrometer positioning accuracy. | Management | 15,00,000 | 28 June 2017 | 3 years | Ongoing | Dr. Muralidhara-PI |

| 12 | Development of Patient Lift System for Justice K S Hegde Charitable Hospital, Deralakatte, Mangaluru. | Nitte University | 16,000 | 2017 | 1 Year | Ongoing | Mr. Melwyn Rajesh Castelino |

| 13 | Design, Development And Testing Of A Screw Press Expeller For Honne Oil Extraction | NID Ahmadabad- MSME Scheme, GoI | 2,00,000 | 6 March 2017 | 1 Year | Completed | Dr. Shashikantha Karinka |

| 14 | Design and Development of Voltage Drive for Piezo-Hydraulic Pump with Active Valves | TEQIP- Phase-II | 80,000 | 2016 | 1 Year | Completed | Dr. Muralidhar |

| 15 | Surface Roughness Optimization During High Speed Machining of Biodegradable Magnesium | TEQIP- Phase-II | 1,05,330 | 2016 | 1 Year | Completed | Dr. Srinivasa Pai P. |

| 16 | Design and Fabrication of a Multiple Biodiesel Seed Decorticator | NID Ahmadabad | 1,02,500 | 26 March 2015 | 1 Year | Completed | Dr. Shashikantha Karinka |

| 17 | Design Fabrication and Testing of Micro pump Manufactured using Tool Based Micromachining Process for Drug Delivery System | VGST | 30,000 | 28 February 2017 | 6 month | Completed | Dr. Muralidhar |

| 18 | Surface Roughness Evaluation of Turned Surface using computer vision system | IE (India) | 15,000 | 31 March 2014 | 1 Year | Completed | Dr.Srinivas Pai P |

| 19 | Modeling and optimization of surface Roughness in Ti- based alloys using vibration monitoring | AICTE, New Delhi | 17,40,000 | 31 March 2013 | 3 Year | Completed | Dr.Srinivas Pai P |

| 20 | Embedded control system design for position & tracking control of a prototype actuator | SERB, DST, New Delhi | 16,14,000 | 20 September 2014 | 3 Years | Completed | Dr.Muralidhar |

| 21 | Investigation on machining depth control in microelectro- discharge machining Process using 3 D Process simulation | VTU, Karnataka | 12,40,000 | 10 December 2010 | 2 Years | Completed | Dr. Muralidhar |

| 22 | Defect Characterization in Antifriction bearing using vibration signal analysis for condition monitoring | VTU Belgaum | 6,50,000 | 3 October 2008 | 4 Years | Completed | Dr. Srinivas Pai P Dr. N.S.Sriram |

Consultancy

The Department offers consultancy/machining services with regard to Alternative fuels and IC engine research lab, surface roughness measurement, Micro hardness, contact angle measurement, Microstructure analysis, Tensile testing, CNC machines, Bio safety lab, casting simulation, 3D printing, casting, non-destructive testing and Welding Technology. The customer shall contact either the Head of Mechanical Engineering Department or the respective staff-in-charge(s) for the usage of the above facility

- CNC- Dr. Grynal D’Mello, Associate Professor / Mr. Bhaskara P Achar, Asst. Professor

- Surface Roughness/ Microhardness- - Dr. Srinivasa Pai, Professor/ Dr. Grynal D’Mello, Associate Professor

- Alternative Fuels/ I. C. Engines - Dr. Narasimha Bailkere, Professor

- Bio Safety Lab - Dr. Nithin Kumar , Associate Professor

- Metallurgy Lab - Dr. Nithin Kumar, Associate Professor

- Welding Automation (custom build special purpose machine) : Dr. Vijeesh V, Associate Professor

- Wire arc additive manufacturing (MIG/TIG/TANDEM) : Dr. Vijeesh V, Associate Professor

- Friction stir welding/processing (aluminium/titanium) : Dr. Vijeesh V, Associate Professor

- 3D Printing ( FDM/ DLP) : Mr. Raghavedra Pai, , Assistant Professor

- Casting/ cooling curve analysis/stir casting : Dr. Vijeesh V, Associate Professor

- Metallographic Analysis (Disc polishing, etching, microstructure) : Dr. Vijeesh V, Associate Professor

- Contact angle analyser : Dr. Vijeesh V, Associate Professor

- Ultrasound Non-destructive Testing / in-situ pipeline corrosion analysis : Dr. Vijeesh V, Associate Professor

Program

- Duration - 4 years

- Semester - 08

- Intake - 120 Students

The Department of Mechanical Engineering is an established Research Centre under VTU Belagavi since the year 2007 offering Ph.D programmes both Part-Time and Full-Time. So far, six candidates have completed Ph.D and 32 have registered for doctoral studies. At present there are three full-time Research scholars. The applicants for Full-time and Part-time Ph.D follow the VTU guidelines for admission. The department has nine faculty members recognized as VTU approved Research Supervisors with diverse research background and exposure, who are dedicated in fulfilling the varied research aspirations of the prospective researchers. From the year 2022-23 Ph.D degree is awarded by Nitte University. The following faculty members are the research supervisors/guides:

| Sl. No. | Research Guides | Research Area |

|---|---|---|

| 1 | Dr. Shrinivasa Rao B. R | I.C. Engines & Combustion, Automotive Engineering, Pollution, Heat Transfer, Theory of Machines Alternative Fuels |

| 2 | Dr. Sudesh Bekal | Solar Energy, Wind Energy, I C Engine, Bio Fuels, Optimization |

| 3 | Dr. Subrahmanya Bhat | Total Quality Management, Six Sigma, Quality Management in Engineering Education |

| 4 | Dr. Shashikantha Karinka | Internal Combustion Engines,Alternative Fuels, Emissions & Pollution control, Automobile engineering, Lean and green manufacturing, Energy conservation and management, Global warming and climate change |

| 5 | Dr. Srinivasa Pai P | Tool Condition Monitoring, Acoustic Emission, Vibration Monitoring, Artificial Neural Networks, Maintenance Engineering & Management, Wavelet and its applications to Machining related areas, High speed machining related areas including wear studies,Surface roughness analysis |

| 6 | Dr. Muralidhara | Tool based micromachining, Micro electro discharge machining, Design of Micro actuators, Active vibration Isolation, Robotics |

| 7 | Dr. Narasimha Marakala | Fluid and Thermal Induced Vibration, Composite materials |

| 8 | Dr. Mallikappa | Alternative fuels, Advanced Manufacturing Science, Measurement Science |

| 9 | Dr. Narasimha Bailkere | Combustion Engineering, Alternative Energy, Sources for IC Engines, Thermodynamics, Turbo machines |

| 10 | Dr. Gururaj Upadyaya | Quality Initiatives , Quality Awards and Performance, Total Quality Management |

| 11 | Dr. Kumar H. S | Bearing Condition Monitoring, Wavelet transform, Feature extraction, Fault diagnosis |

Apart from the regular faculty members for research work supervision, the Department also draws its support from the two distinguished adjunct Professors, who were with prominent Indian multinational corporate companies.

The Research Centre has five centres of Excellence consisting of six different research areas such as micromachining, advanced machining, condition monitoring, engine alternative fuels, vibration isolation, system modelling & design with adequate equipment and software back-up for research work.

The Research centre is also getting the support through sponsored research projects as follows:

- Ongoing Project: Karnataka Council for Technological up gradation and NMAM Institute of technology, Nitte. Rs. 77.28 Lakhs (50% own fund) worth project sanctioned on center for Tool based Micromachining Research. Another 10.17 lakhs funding has been received through AICTE.

- Completed Projects: Total Rs. 91.57 Lakhs of various funded projects were completed during 2010-2017. The funding agencies are VTU Belagavi, AICTE New Delhi and VGST Karnataka.

The list of research scholars under NMAMIT : Click Here

Placements

Post Doctoral Fellowship

Dr. Ajit Hebbale, Associate Professor, Department of Mechanical Engineering, successfully completed One-year Post Doctoral Fellowship at International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), Hyderabad, (DST Lab, Govt. of India), on a research topic entitled " A Comparative Study on Characteristics of Composite Clads Developed through Diode Laser and Microwave Energy” on 31 July 2020.

Awards

| Sl. No. | Year | Name of the Faculty | Name of the Award |

|---|---|---|---|

| 1 | 2022 | Dr, Vijeesh V | Best paper award in National conference on 3D PRINTING & ADDITIVE MANUFACTURING TECHNOLOGY organised by Department of Mechanical Engineering, Bangalore Institute of Technology and AICTE , New Delhi at Bengaluru for the paper “Effect of Process Parameters on Wire arc additive manufacturing of Stainless steel (308L) for biomedical applications” 23-24th May 2022. |

| 2 | 2022 | Dr. Grynal D’Mello, Dr. Srinivasa Pai P | Best Technical Session Award for the paper entitled ‘Surface Roughness analysis in High Speed Turning of Ti-6Al-4V with coated carbide inserts using Vibration Signals’ during an International Conference on Futuristic Advancements in Materials, Manufacturing and Thermal Sciences – ICFAMMT 2022 jointly organized by the Department of Mechanical and Aerospace Engineering, IITRAM Ahmedabad, & Space Society of Mechanical Engineers (SSME), Space Applications Centre, ISRO, Ahmedabad during 20 – 22 January 2022. |

| 3 | 2021 | Dr Vijeesh V | Recieved prestigious William Spraragen Memorial Award for year 2021 from American Welding Society (AWS) for paper “Four Types of LME Cracks in RSW of Zn-Coated AHSS” Published Welding Research Journal in the March 2020. |

| 4 | 2020 | Dr. Srinivasa Pai P | Selected for the Leadership For Academicians Programme (LEAP), MHRD, Govt. of India at IIT Kharagpur from Nov 11-22, 2019 and at IfM, University of Cambridge, UK from Jan 6-10, 2020. |

| 5 | 2020 | Dr. Grynal D'mello Dr. Srinivasa Pai P |

PhD Thesis entitled “SURFACE ROUGHNESS MODELING AND OPTIMIZATION IN TITANIUM BASED ALLOYS USING VIBRATION IN HIGH SPEED MACHINING” has been selected for BITES Special Mention of the Jury for the year 2020, in the category of Other branches with significant IT / CA related contents. |

| 6 | 2017 | Dr. Muralidhara | First consolation prize for the presentation of his research work in the exhibition of Academia project at IMTEX-2017 |

| 7 | Dr. Muralidhara | [Final year students project exhibition & competition] Project of the year award | |

| 8 | 2016 | Mr.Grynal D’Mello | BEST PAPER AWARD for Surface roughness Modelling in High speed Tuning of Ti-6Al-4V - Artificial Neural Network Approach at ICAMM-2016 at MLRIT, Hyderabad |

| 9 | Dr.Muralidhara | Theoretical Investigation on Piezowafer Actuated Micropump. ICETE-2015 | |

| 10 | 2015 | Dr. Muralidhara | First Place for their research work on “Investigation on mechanical micromachining process with piezo actuated machining depth control and its application in MEMS device fabrication” at the IMTEX Exhibition – 2015 |

| 11 | Dr. Muralidhara | Expro -2014: Project of the Year Award for “Design & Development of an Unmanned, Remotely Controlled Multi utility Micro Air Vehicle” | |

| 12 | Dr. Muralidhara | Certificate of Achievement for having guided the ISTE-GSFC National Award for Best M. Tech Thesis | |

| 13 | 2014 | Dr. Muralidhara | Second consolation prize for the presentation of his research work in the exhibition of Academia project at IMTEX Exhibition – 2014 |

| 14 | Dr. Narasimha Marakala | Best paper award in ICETE-2013 held at J. J. Mugdam College of Engg., Kolhapur | |

| 15 | 2013 | Dr. Muralidhara | Best paper award in international conference held at Shri Eshwar College of Engineering |

| 16 | Dr. Narasimha Bailkeri | Best paper award in the International Conference RACE-2012 held at MIT Manipal | |

| 17 | 2012 | Dr. Srinivasa Pai P Adarsh A Rai |

Certificate of Achievement for having guided the Best M.Tech Thesis (II Prize) |

Clubs & Chapters

About AIMS

Association for Interaction of Mechanical students (AIMS) is a body of the Mechanical Engineering students of NMAM Institute of Technology, Nitte. AIMS provides opportunities to build leadership qualities, team work, and personality development and exhibit professional and technical skills. It conducts invited talks, seminars, workshops and technical events helping students build a career with professional, ethical and technical values and skills.

About CSMI

Condition Monitoring Society of India (CMSI) was established in 2003 by a team of scientists, academicians, engineers and maintenance practitioners with the noble aim of furthering the implementation of condition monitoring methodologies in Indian Industrimsies. The Society headquarters is located at Visakhapatnam, with a number of active Chapters throughout India. Condition Monitoring Society of India (CMSI) NMAMIT-student chapter started in 2014 under the guidance of Dr. Srinivasa Pai and the former HoD Dr. Subrahmanya Bhat K. Postgraduate students of MAchine Design and Undergraduate students of Mechanical Engineering are the members of this chapter. CMSI NMAMIT-Student Chapter conducts Industrial visit to the various nearby industries and organizes technical talks for students by variousindustry experts and Professors from institutes who are woking in this field there by giving exposure to the students in recent developments in Condition Monitoring. Mr. Dilip Kumar K, Assistant Professor, Department of Mechanical Engineering, is the Staff Coordinator for CMSI-NMAMIT Student Chapter from the academic year 2017-18

Activities conducted (2019-2020)

- An Industrial visit to Bell O Seal Valves Pvt Ltd, Santhekatte, Udupi was arranged on 11 January 2020. 18 CMSI student members of UG Mechanical Engineering and M. Tech - Machine Design along with four faculty of the Department visited the plant.

- Organized a Guest Lecture on Usage of FLIR make thermal imagers in different applications, test and measuring instruments (FLIR & EXTECH make) for industries / R&D centres by Eagle Electricals, Bangalore on 07 February 2020.

- Organized a Guest Lecture on Role of Plastic Deformation to Improve Tribological Properties of a variety of Engineering Materials" by Dr Udaya Bhat K, Professor, Department of Metallurgical and Materials Engineering, NITK Surathkal, on 28 February 2020.

About Club

Aero Club is a technical club started in 2011 – 2012, to pursue ideas in the field of aero modelling and related areas. Mr. Divin Bharadwaj, was the student team leader during the first two years of its inception. The club with the guidance of the faculty coordinator of the club is Dr. Gururaj Upadhyaya is successfully organizing its activities for the past 13 consecutive years. The students have participated and won prizes at prestigious national level competitions. The following is the list of prizes won by the students in the recent past.

| Sl. No. | Event Name | Prize | Date |

|---|---|---|---|

| 1 | SAE India – Southern Section Aero Design Challenge 2022 | II | 1 - 3 September 2022 |

| 2 | 2 teams of Aeroclub, with 6 participants participated in Engineer 2K2. One of the teams won second prize. | II | 23 - 24 September 2022 |

| 3 | Skydive at Shayadri College of Engineering | I,II | 12- 13 November 2022 |

| 4 | Skydive at Shayadri College of Engineering | I,II | 12- 13 November 2022 |

| 5 | Boeing IIT National Aeromodelling Competition, IIT Bombay | II | 16-18 December 2022 |

| 6 | Boeing IIT National Aeromodelling Competition, IIT Madras | II | 26 - 27 January 2023 |

| 7 | Boeing IIT National Aeromodelling Competition, IIT Kanpur | I,II,III | 25 March 2023 |

| 8 | Flightfury, Organized by IIT, Rookee | II | 24 - 25 March 2023 |

| 9 | AeroHelix at IIT, Roorkee | III | 24 - 25 March 2023 |

| 10 | 8th Boeing IIT National Aeromodelling Competition, Final Round RVCE, Bangalore | II, III | 29 April 2023 |

| 11 | SAE India – Southern Section Drone Design Challenge 2023 | I | 23 July 2023 |

| 12 | Wright Flight, NITK Surathkal | II | 14 and 15 October 2023 |

| 13 | Boeing IIT National Aeromodelling Competition, Zonal event at IIT, Madras | I,II | 21 December 2023 |

| 14 | Boeing IIT National Aeromodelling Competition, Zonal event at IIT, Bombay | III | 29 December 2023 |

| 15 | Boeing IIT National Aeromodelling Competition, Zonal event at IIT, Kharagpur | I,II, III | 21 January 2024 |

Major Activities

- Within NMAMIT –

- Organizing Workshops on Basic Aero modeling

- Building of Remote Controlled (R. C) Aircrafts

- Conducting Aero Exhibitions and Air shows

- Star Gazing programmes

- R. C Aircraft flying competitions (Aeromania)

- Assisting student projects in the areas of R. C Aircrafts and drones

- Presentation of technical papers related to the projects undertaken with the assistance of aero club.

- Outside NMAMIT - Participation in national and local R. C. Aircraft flying completions (such as Boeing IIT national aero modeling competition)

- Incorporation of a Start up Airmydus Technologies (INFINITY DRONES) by former members of the Aero Club.

- Selection of a student, Mr. Karthik Rao B., as one of the top 12 pilots of the nation to compete at Boeing IIT National Aeromodeling completion (Finals) at IIT Delhi.

- First runner up at Boeing IIT National Aeromodeling completion at IIT Kanpur.

- Runner Up at AIR-PURSUIT ( RC aeromodeling and Flying competition), held at Sri Devi Institute of Technology, Mangalore.

- Second place in State Level Technical Paper presentation organized by IEI, Nitte Chapter.

Major Achievements

- Design and fabrication of Hexarotor (2013-14)

- Automated Stabilization of Unmanned Aerial Vehicles (2015-16) – Mini project

- GPS Automated Quadcopter with Facial Recognition Camera (2015-16)

- Unmanned aerial navigator, terrestrial investigator and surveillance (2016-17)

- Solar powered radio controlled plane (2016- 17)

- Ongoing Projects

- High altitude aeronautical platform station ( Special project, KBITS funded, ongoing since 2016)

- Low altitude Aerial Pesticide sprayer with real time crop health monitoring (Projects to be undertaken by Final year students during 2017-18)

About Robotics Club

Robotics Club - an interdisciplinary Club under Mechanical Engineering Department was- formed in the year 2014 at NMAM Institute of Technology with a motive to provide hands-on experience on various applications of robotics. Student members of the Club participated in different robotics competitions at various colleges and won many prizes. The club also conducts workshops to develop skill in building robots.This lab gives an exposure to the students of various disciplines to work on multi-disciplinary projects.

SAE BAJA

The BAJA SAEINDIA event is one of the prestigious and exhilarating events organized by SAE India.

It is an inter collegiate event that demands the students to design and fabricate an off road vehicle. This requires sound knowledge of engineering concepts and practices. With a solid workforce, budding juniors, supporting faculty and with the backing of our alumini, Team NITTE Racing, the official Baja team of NMAMIT, has been fabricating safe, rigid and powerful vehicles which are capable to cross all Endurance and overcome all terrain since 2013. The ATV has received praises for its run in events like SAE Baja and Mega ATV Championship.

SAE SUPRA

Supra (super racing) is a national level engineering student's competition where teams from various engineering colleges participate. In this competition, students design and fabricate a formula class vehicle. The students not only design the vehicle but also fabricate it as per the given set of rules (rule book) and design standards of SAE international. The Supra SAE India - Student Formula 2017 edition was held at Buddh International Circuit, Greater Noida. It was scheduled during 26 June - 1 July 2017. Student teams from 126 engineering colleges across the country participated in this event. Each team consisted a maximum of 25 students in it. 9 colleges from the state of Karnataka participated in the event. "Formula Nitte" representing NMAM Institute of Technology, Nitte also made their debut in the event. A total of 112 ranks were allotted at the end of the competition. Formula Nitte secured an All India Ranking of 32, standing II in the state of Karnataka.

Conditioning Monitoring Society of India

Condition Monitoring Society of India (CMSI) was established in 2003 by a team of scientists, academicians, engineers and maintenance practitioners with the noble aim of furthering the implementation of condition monitoring methodologies in Indian Industries. The Society headquarters is located at Visakhapatnam, with a number of active Chapters throughout India. Condition Monitoring Society of India (CMSI) NMAMIT-student chapter started in 2014 under the guidance of Dr. Srinivasa Pai and the former HoD Dr. Subrahmanya Bhat K. Postgraduate students of Machine Design and Undergraduate students of Mechanical Engineering are the members of this chapter. CMSI NMAMIT-Student Chapter conducts Industrial visit to the various nearby industries and organizes technical talks for students by various industry experts and Professors from institutes who are working in this field there by giving exposure to the students in recent developments in Condition Monitoring. Mr. Dilip Kumar K, Assistant Professor, Department of Mechanical Engineering, is the Staff Coordinator for CMSI-NMAMIT Student Chapter from the academic year 2017-18.

About SESI

The Solar Energy of India (SESI), established in 1976, with its Secretariat in New Delhi, is the Indian Section of the International Solar Energy Society (ISES). Its interests cover all aspects of renewable energy, including characteristics, effects and methods of use, and it provides a common ground to all those concerned with the nature and utilization of this renewable non-polluting resource.

- Publication of SESI Journal, a bi-annual technical journal containing papers on renewable energy utilization, Publication of a monthly news letter, namely the SESI News Letter.

- Organization of one –day workshops on selected topics.

- Organization of the International Congress on Renewable Energy once in a year, where numerous scientific and technical papers are presented and discussed & these proceedings are published and released Annual during Convention.

Under the SESI chapter there has been five industrial visits, Bola cashew Industry, UPCL Padubiri, Hirgana rice mill, Suzlon wind blades etc were in the students had an opportunity to interact with industry personnel and see the factory working also deputy general manager of UPCL Mr. Parashuram. There has been an Inspirational Invited talk by Mr. Oliver Sutari.

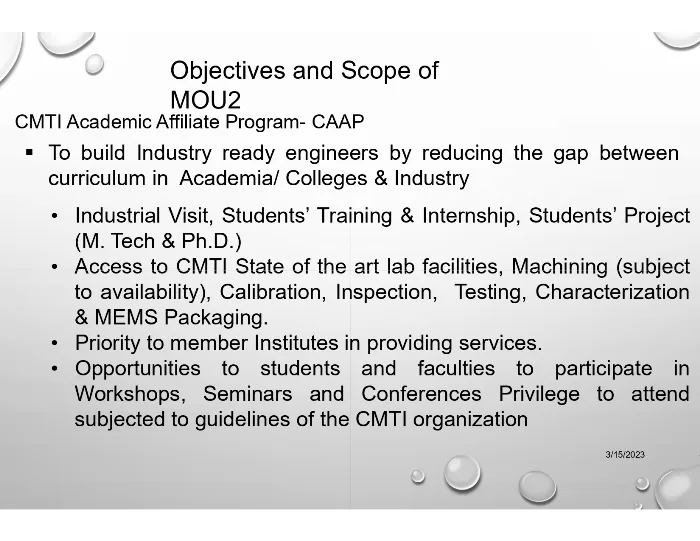

MoUs